Empa launches information platform

“Additive Manufacturing” speeds up

Empa offers Switzerland a platform to exchange information and knowhow in the field of Additive Manufacturing: During a technology briefing held at Empa Academy on January 18, experts from industry and research learned about the latest developments in this pioneering technology, which is also extremely important from an economic perspective.

Empa’s latest technology briefing just goes to show how important Additive Manufacturing (AM) is set to become for Switzerland: Over 150 people from industry and research convened for the Empa Academy event Additive Manufacturing – Quo vadis II on January 18 to swap ideas on future developments in industrial 3D printing, quality control and novel design approaches. The event is held every two years.

New design approaches and business models have already established additive production processes at the heart of the manufacturing industry. For instance, smaller special parts for the production of chocolate bars tailored to the specifications of the customers are already manufactured using 3D printing, which slashes the cost of each component tenfold. And AM is also used in the professional camera aperture sector for small series that can be delivered rapidly based on web-based software which enables the parameters of the pieces requested to be specified by the customers themselves.

Customized skin, muscles and replacement cartilage

The use of AM is also already common practice in medical engineering, such as for knee, face and spinal implants. In the near future, experts expect surgical screws and implants made of magnesium that dissolve in the body and no longer need to be removed (via another operation). The dissolving speed can be controlled through the material, the design of the implant and the production process in the 3D printer. In a few years, it might even be possible to print artificial cartilage, muscles or skin, which can then be implanted in patients.

A recurring problem in 3D printing was also raised at Empa’s technology briefing: the formation of cracks in the workpiece. Research at EPFL reveals that the problem can be solved using a technique borrowed from turbine construction: The material is shaken with the aid of ultrashort laser impulses, which homogenizes the structure and reduces internal tension. Consequently, components might be produced on a 3D printer in future that are on a par with their conventionally manufactured counterparts in terms of solidity.

The additive processing of ceramic materials also harbors enormous potential. However, it faces major challenges. The high proportion of binding agents that has been necessary in ceramic pastes thus far often causes problems when processed further. Therefore, researchers are working on new approaches as to how nanopowders can be used and binding agents reduced, for instance. The sintering of the particles is also far from trivial and the subject of intensive research.

Expert groups and networks offer advice and guidance

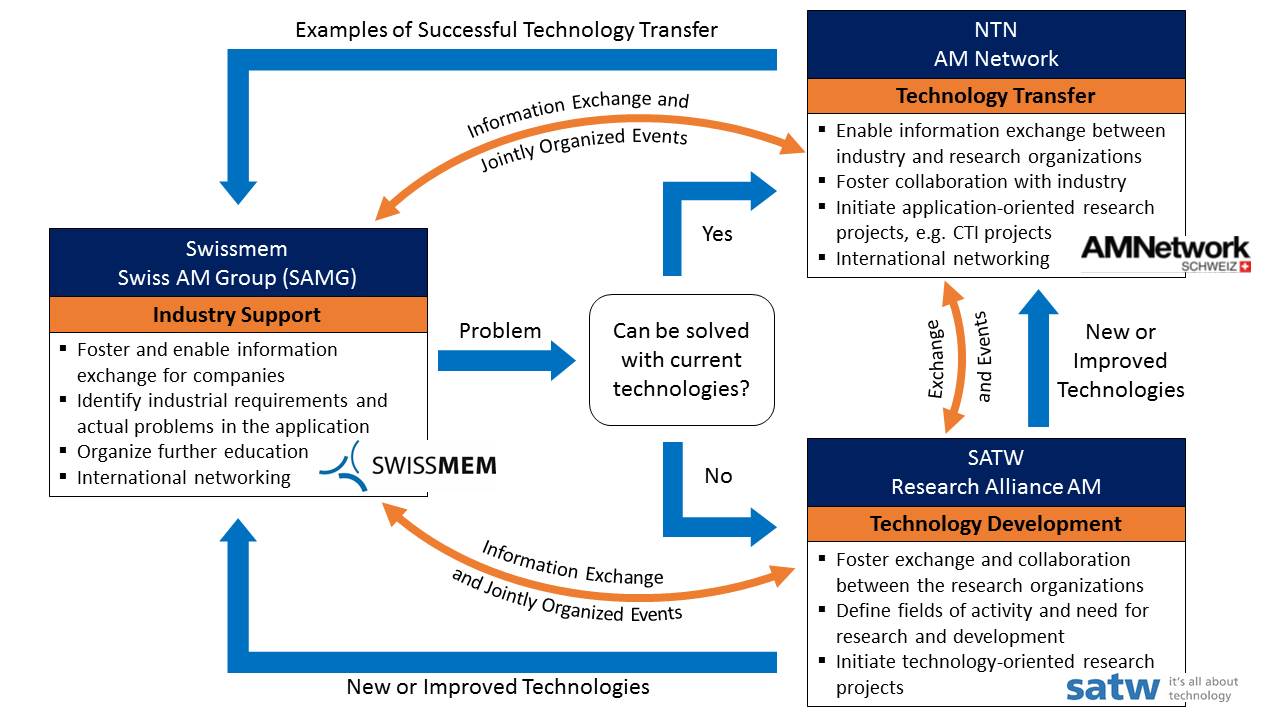

At the end of the event, different expert groups and networks who are looking to bring together the various actors in AM and network them more effectively introduced themselves to promote the topic even further. Many of these initiatives were only instigated last year, such as the Research Alliance AM at the Swiss Academy of Engineering Sciences (SATW), the AM Network Switzerland of the Commission for Technology and Innovation (CTI), and the Swiss AM Group (SAMG) of the industrial association Swissmem.

Dr. Pierangelo Gröning

Dept. Advanced Materials and Surfaces / board of directors

phone +41 58 765 40 04

pierangelo.groening@empa.ch

Dr. Christian Leinenbach

Advanced Materials Processing

phone +41 58 765 45 18

christian.leinenbach@empa.ch

Prof. Dr. Patrik Hoffmann

Advanced Materials Processing

phone +41 58 765 62 62

patrik.hoffmann@empa.ch

- «Additive Manufacturing» at Empa

- Empa: Alloy Design for Advanced Processes

- Empa «Technology Briefing» background information

- Strategic Focus Area Advanced Manufacturing at ETH Domain

- CCMX Materials Challenge – Additive Manufacturing and Metallic Microstructures (AM3)

- Platform Additive Manufacturing der SATW (Swiss Academy for Engineering Sciences)

- Commission for Technology and Innovation (CTI) – AMNetwork Switzerland

- Swissmem Fachgruppe SAMG (Swiss Additive Manufacturing Group)

- Swiss Engineering Fachgruppe Additive Manufacturing

-

Share