Printed Cellulose Materials & Devices

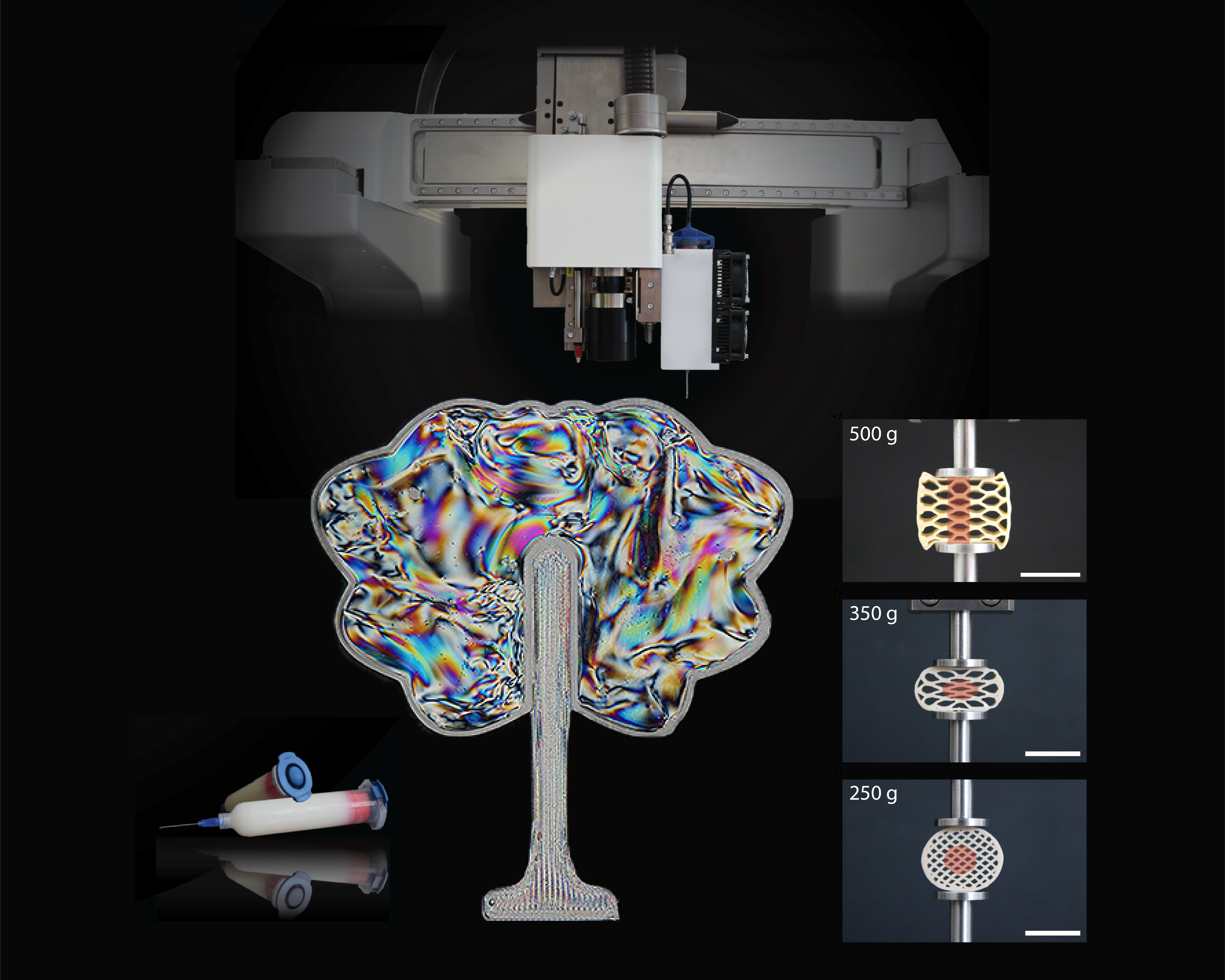

Cellulose is an important functional element in plants where it forms structures that regulate water and nutrient transport and assemble into hierarchical structural units with high specific mechanical strength and toughness. Inspired by nature, our work in this area use cellulose in the form of renewable biological and biodegradable colloids, Cellulose Nanocrystals and Cellulose Nanofibrils, as starting materials to produce inks that are then used to print materials and devices. Specifically, our research has demonstrated that nanocellulose can be used to efficiently disperse functional nanomaterials and that it is possible to work with high nanocellulose loadings (up to 35 wt%) in these colloidal gel inks. The resulting sustainable technologies benefit from a resource and energy efficient digital manufacturing and have functionalities resulting both from the ink constituents and from the printed structure itself such as shape morphing, stimuli-responsiveness and tunable biodegradation. The applications that we target include lightweight composites, biomedical scaffolds and devices and integrated sensing structures for e.g. environmental, health and food quality monitoring.

Selected Publications

Cellulose nanocrystal inks for 3D printing of textured cellular architectures. Gilberto Siqueira et al. Advanced Functional Materials, 27(12): 1604619 (2017).

Dynamics of Cellulose Nanocrystal Alignment during 3D Printing. Michael Hausmann et al. ACS Nano 12(7): 6926-6937 (2018).

3D Printed Disposable Wireless Ion Sensors with Biocompatible Cellulose Composites. Taeil Kim et al. Advanced Electronic Materials 5: 1800778 (2019).

Complex-Shaped Cellulose Composites Made by Wet Densification of 3D Printed Scaffolds. Michael Hausmann et al. Advanced Functional Materials 30: 1904127 (2020).

Mechanical Properties Tailoring of 3D Printed Photoresponsive Nanocellulose Composites. Luca Müller et al. Advanced Functional Materials 30: 2002914 (2020).

3D printing of shape-morphing and antibacterial anisotropic nanocellulose hydrogels. Olivier Fourmann et al, Carbohydrate Polymers 259: 117716 (2021).

Fully 3D Printed and Disposable Paper Supercapacitor. Xavier Aeby et al, Advanced Materials, 33(26): 2101328 (2021).

Reports in media

Wood on our skin – flexible, biocompatible nanocellulose sensors. Empa Press Release

Wearable health. EmpaQuarterly 68

Ears from the 3D printer. Empa Press Release

3D printing some of the world’s lightest materials. Nature Podcast

Related projects

Digital Manufacturing of 3D-Printed Wearable Sensors (D-SENSE) – ETH SFA AM (2017-2021)

Toolbox of functional bio-based inks: 3D printing of novel multiscale structured composites inspired by nature (MULTIFUN) – SNF (2018-2022)

Green Smart Packaging (GREENsPACK) – Bridge Discovery (2020-2024)