Laser processing: Selected projects

Laser processing of hard and transparent materials

Processing of diamond and sapphire (Al2O3) have always attracted considerable attention. However, due to their extreme hardness, machining hard into specific geometric forms remains a grand challenge.

Research at Empa focused on developing specific laser processes with different sources (spectral and temporal resolutions).

The major achievement is a demonstration of; (a) a nanosecond (ns) pulse laser was better than short or ultra-short pulse laser in terms of efficiency, (b) phase transformation and sub-surface cracking by tuning the laser power, (c) optimal laser beam strategy and laser wavelength. Additionally, the development of semi-empirical models based on design of experiment (DoE).

Schematic of the laser process developed of hard and transparent materials

Selected publications

-

Mouhamadali F., Equis S., Saeidi F., Best J.P., Cantoni M., Hoffmann P., and Wasmer K., “Nanosecond Pulsed Laser-Processing of CVD Diamond” Optics and Lasers in Engineering, Vol. 126, Issue March 2020, paper ID: 105917, 2020,

https://doi.org/10.1016/j.optlaseng.2019.105917 -

Saeidi F., Mouhamadali F., and Wasmer K., “Nanosecond Laser Ablation of Different Crystallographic Planes of Sapphire”, Presented at Laser in Manufacturing (LiM2017), Munich, Germany, 26 – 29 June, 2017.

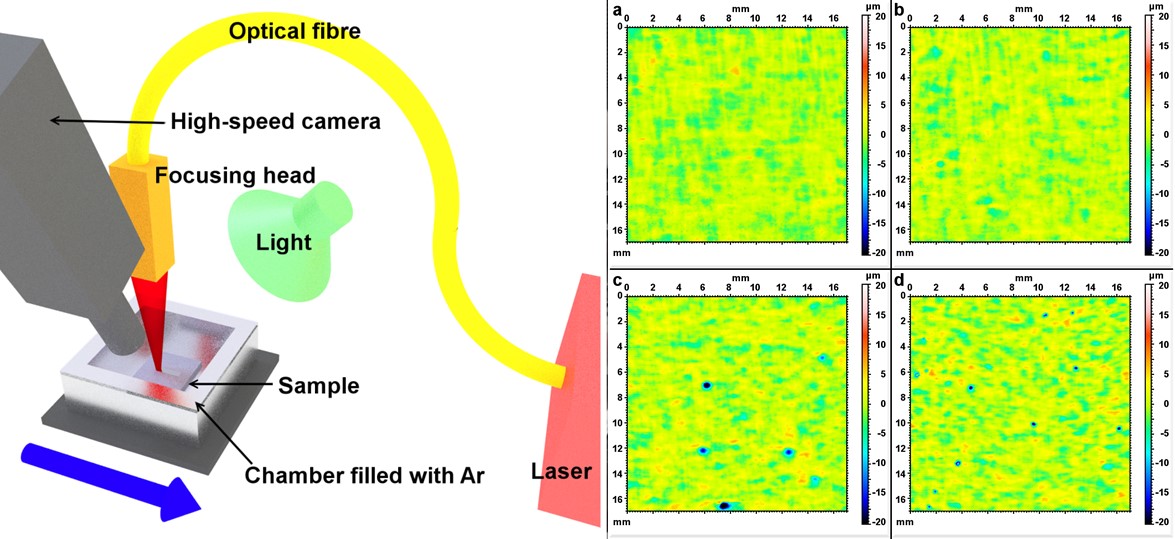

Laser polishing of tool steel

Laser polishing (LP) of materials aims to decrease the surface roughness of materials without contact. This is achieved by ablating and melting the surface by laser irradiation. LP in metals is employed in the conduction regime, where a small volume of the material is melted by the laser beam. During the melting, the asperities are smoothed by the action of surface tension aided by an increased mobility of the liquid state.

Research at Empa focused on developing a new process maps by combining fundamental understanding of the process and design of experiment (DoE) approaches. The major achievement was to provide both robust process maps and semi-empirical models of the laser polishing process of tool steel.

Selected publications

- Meylan B., Calderon I., Le-Quang T., and Wasmer K., "Investigations of Surface Defects during Laser Polishing of Tool Steel " Procedia CIRP, Vol. 94, Issue 2020, pp: 942–946, 2020,

https://doi.org/10.1016/j.procir.2020.09.092

Laser processing using a wobbling head

Laser beam welding (LBW) coupled with “wobble effect” (fast oscillation of the laser beam) is a very promising technique for high precision micro-joining industry. Welding using a small wobbling laser spot (30 µm – keyhole welding) has several advantages as compared to the conventional LBW (conduction welding). They includes faster processing speed, larger welding penetration, larger welding area, smaller heat-affected zone (HAZ). However, it is known that keyhole welding is more prone to defects, so the quality is more dependent from the slight changes in the process parameters.

Research at Empa focused on developing a new process maps by combining fundamental understanding of the process and design of experiment (DoE) approaches. The major achievement was to provide both - robust process maps and semi-empirical models of the wobbling welding process.

Selected publications

-

Le-Quang T., Vakili-Farahani F., Faivre N., and Wasmer K., "Energy-Efficient Laser Welding With Beam Oscillating Technique – A Parametric Study" Journal of Cleaner Production, Vol. XX, Issue: X, Paper ID: XX, pp: 1-XX, 2021,

https://doi.org/10.1016/j.jclepro.2021.127796 -

Le-Quang T., Shevchik S.A., Meylan B., Vakili-Farahani F., Olbinado M.P., Rack A., and Wasmer K., “Why Is In Situ Quality Control of Laser Keyhole Welding a Real Challenge?” Procedia CIRP, Vol. 74, Issue 2018, pp: 649–653, 2018,

https://doi.org/10.1016/j.procir.2018.08.055 -

Vakili-Farahani F., Lungershausen J., and Wasmer K., "Wavelet Analysis of Light Emission Signals in Laser Beam Welding", Journal of Laser Applications, Vol. 29, Issue 022424, pp: 1-7, 2017,

http://dx.doi.org/10.2351/1.4983507 -

Vakili-Farahani F., Lungershausen J., and Wasmer K., “Process Parameter Optimization for Wobbling Laser Spot Welding of Ti6Al4V Alloy“, Physics Procedia, Vol. 83, pp: 483-493, 2016,

http://dx.doi.org/10.1016/j.phpro.2016.08.050