Direct Ink Writing

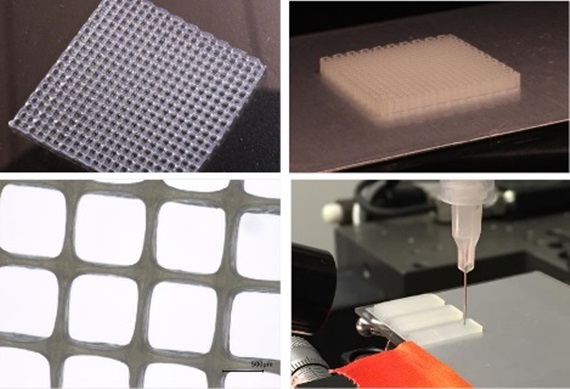

Direk Ink Writing (DIW) is a 3D printing technique in which materials are deposited in a layerwise method, by continuous rising of the print head, in order to create a 3D structure. The material is processed as a paste or as pellets. The viscosity of the paste or the melting temperature of the pellets are an important parameters.

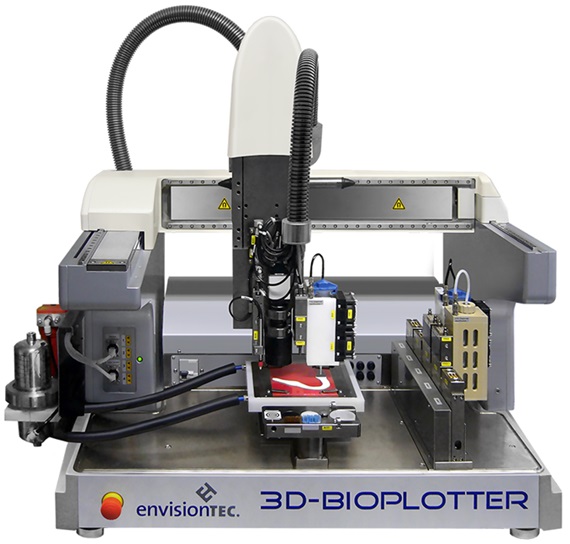

3D bioplotter "Manufacturer Series"

The 3D printer, as an important component of Coating Competence Center Empa, provides an ideal platform to process material and carry out research for additive manufacturing of precise three-dimensional structures.

The device is ideal for processing a wide variety of liquid or solid materials such as biopolymers, pastes from ceramic or metal powders, thermoplastics, hydrogels, organic monomers or nanomaterials, such as graphene. Using both low and high temperature extruding nozzles, materials can be processed as pastes or solid polymers which will be then melted prior to printing. The building platform is temperature controlled and allows to control the temperature of the build during and after printing.

Technical data of 3D Bioploter

| Axis Resolution (X, Y, Z) | 1 μm |

| Speed | 0.1 to 150 mm/s |

| Pressure | 0.1 to 9.0 bar |

| Max. Build Volume (X, Y, Z) | (150 x 150 x 140) mm |

| Needle Position Control | Z-Sensor + HR Camera |

| Camera Resolution | 9 μm |

| Min. Standard Diameter | 0.1 mm |

| N° of Material per Scaffold | Maximum 5 using 5 Printing Heads |

| Print Specification | Low Temperature Head (0 to 70 °C) |

| High Temperature Head (30 to 250 °C) | |

| Air Filters | Particle and Sterile Filters |

| Platform Temp. Control | Heating and Cooling (-10 to 80°C) |

-

Share