Photonic Curing – PulseForge 1300

The PulseForge 1300 system from NovaCentrix is a research and development tool for rapid photonic curing with pulsed light from a powerful xenon flash lamp.

What is photonic curing?

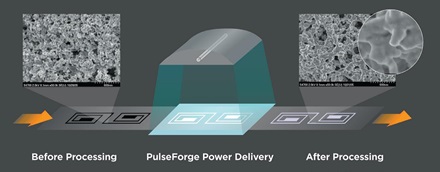

Photonic curing is the high temperature thermal processing of a thin film using pulsed light from a xenon flash lamp. When this transient processing is done on a low temperature substrate such as plastic or paper, it is possible to attain a significantly higher temperature than the substrate can ordinarily withstand in a conventional oven.

Photonic curing (Image: NovaCentrix)

Key specification

- Max radiant energy delivered (J/cm2) 45

- Peak radiant power delivered (kW/cm2) 24

- Output spectrum (nm) 200–1500

- Pulse length range (microseconds) 25–10,000

- Max pulse rate >kHz

- Effective max linear processing speed (meters/min) 30

- Max area cured per sample (mm) 300 x 150

- Environmental chamber for controlled atmosphere and substrate heating

Photonic Curing System PulseForge 1300

Examples of processed materials

Image: DTF Technology

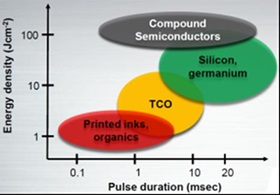

Depending on the pulse energy, duration, shape and repetition several effects can be tailored ranging from drying and curing to defect anneling, sintering and re-crystallization. Examples of processed materials include printed metal and carbon-based inks, compound semiconductors and even refractory oxides. You find more information on the webpages of the Laboratory for Thin Films and Photovoltaics.

-

Share