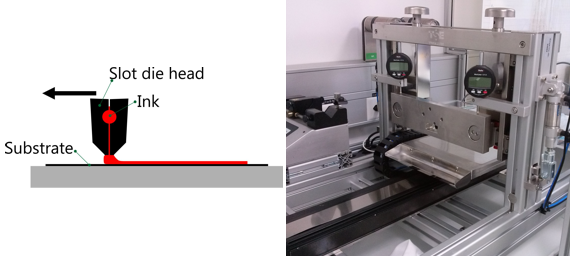

Slot Die Coating

Slot die coating is a processing technique for the deposition of homogeneous wet films. Liquid is delivered through a fixed slot gap onto a moving substrate. Between die and substrate a so-called coating bead forms, bounded by the upstream and down-stream menisci. It is usually used to coat large areas or stripes with high uniformity by precise metering the ink and dispensing it at a controlled rate on the moving substrate.

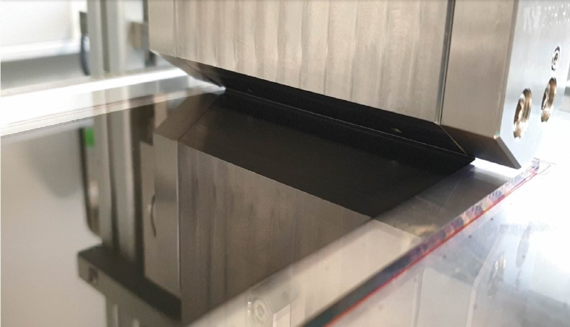

Schematic of the slot die coating process and TSE Troller Slot Die Coater

Key features

- Coating of organic or inorganic inks on flexible or rigid substrates

- Non-contact method

- Coating of large-area / stripes

- Homogeneous films with high uniformity

- Applicable to roll-to-roll processing

- Broad range of viscosities (from < 1 mPa⋅s to several thousand Pa⋅s)

- Film thickness range is large (from 20 nm to approx. 150 nm)

-

Share