DroneHub – Aerial Innovation for a Sustainable Future

The DroneHub will be a test environment that facilitates the integration and interaction of robots such as drones or climbing robots with infrastructure systems. Leveraging the ability of robots to act autonomously, the DroneHub serves as test-bed to perform challenging tasks and thus lowering both the risks for humans and the cost of operation. This includes the inspection of façade elements, repairs of cracks or surface cleaning in areas which are dangerous for humans to work in. To provide a realistic setting for further tests and development, the DroneHub is integrated at NEST, the experimental research and innovation platform of Empa and Eawag.

The DroneHub has been developed by the Empa Laboratory of Sustainability Robotics in collaboration with Imperial College London and EPFL.

The DroneHub is open to industry partners and academia for their own needs. Partnerships may include:

- The use of the DroneHub infrastructure

- Joint R&D initiatives in aerial robotics, robot autonomy, and infrastructure digitalization

- Joint applications to funding calls and co-development of case-studies

- Exchange programs and talent recruitment (sabbaticals)

- Access to technology foresight in aerial robotics and infrastructure robotics and applied AI

- Access to the NEST network of partners from research, industry and the public sector

- Visibility of the logo and use of the NEST infrastructure for events and visits

The DroneHub will include the following features and infrastructure

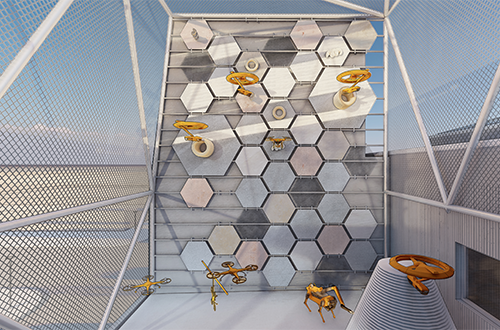

Aerial additive manufacturing façade

Need and vision

Robotic repair and construction methods promise advancements in material efficiency, production efficiency, and safety. Aerial additive manufacturing (AAM) facilitates multi-agent parallel additive manufacturing with an unrestrained built envelope in hard-to-access zones. This allows maintenance tasks such as crack repair to be performed at height without scaffolding or supporting infrastructure and free-form construction at height.

Experimental platform

A vertical aerial additive manufacturing area allows operating drones for infrastructure inspection and repair tasks. The wall of this area features a structure with exchangeable surface elements to perform repair tasks on various surfaces. This allows the printing technology's characterization, evaluation and optimization and ensures that the system performance can be verified. Of unique benefit is the outdoor setting within a building structure, allowing flights at various heights and proximities to structures in adaptable outdoor conditions, representing a realistic environment for system validation in wind, turbulence and ground effects.

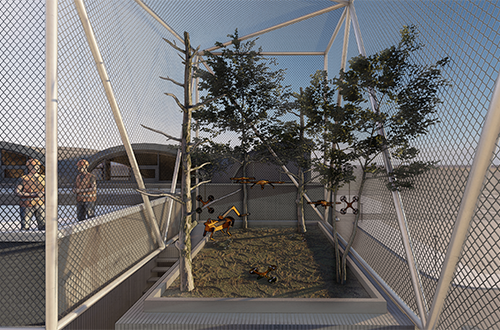

Biosphere for environmental sensing

Need and vision

Today's environmental challenges require novel sensing technologies to derive the appropriate response and measures to limit the impact on the climate. To validate climate models, researchers require datasets with higher temporal-spatial resolution than the ones available today, especially to monitor the impact on sensitive environments. Robotics and AI is the toolbox that can revolutionize the sector. New ap-proaches to sensor deployment, data analysis and residential robots are being developed by the Empa Sustainability Robotics and will be deployed in forests, lakes and on glaciers in near future.

Experimental platform

An area for operations of robotic systems designed to interact with natural features and sustainable robot systems is implemented and includes a biosphere environment to study and demonstrate novel robotic sensing technologies, including novel aerial, climbing and ground based robotic platforms for sensor deployment. The biosphere is designed to enable the testing of transient robots made from biodegradable materials through long-term degradation tests in a real-world setting. Additionally, in view of a sustainable robot economy, a part of this biosphere area is utilized as a greenhouse for growing biohybrid robotic structures.

Infrastructure robotics interface

Need and vision

As a technology enabler, the Coexistence Interface includes the installation of façade elements to integrate interactive elements for robot deployment and define design standards for drone deployment. This stage strongly focuses on building the integration of robotic systems capable of taking over challenging or dangerous tasks for humans.

Experimental platform

Part of the unit is transformed into a lab space for robot testing, enabling the deployment of robots for an integrated living. The experimental façade interface faces the area inside the net to allow access for adjustments of the integrated systems and a safe zone for test flights. This allows us to perform test flights without special permits due to the flight area being restricted by a net. The interface enables testing of Non-Destructive Evaluation methods with aerial robotic systems and AI supported damage analysis.