Architectured Materials

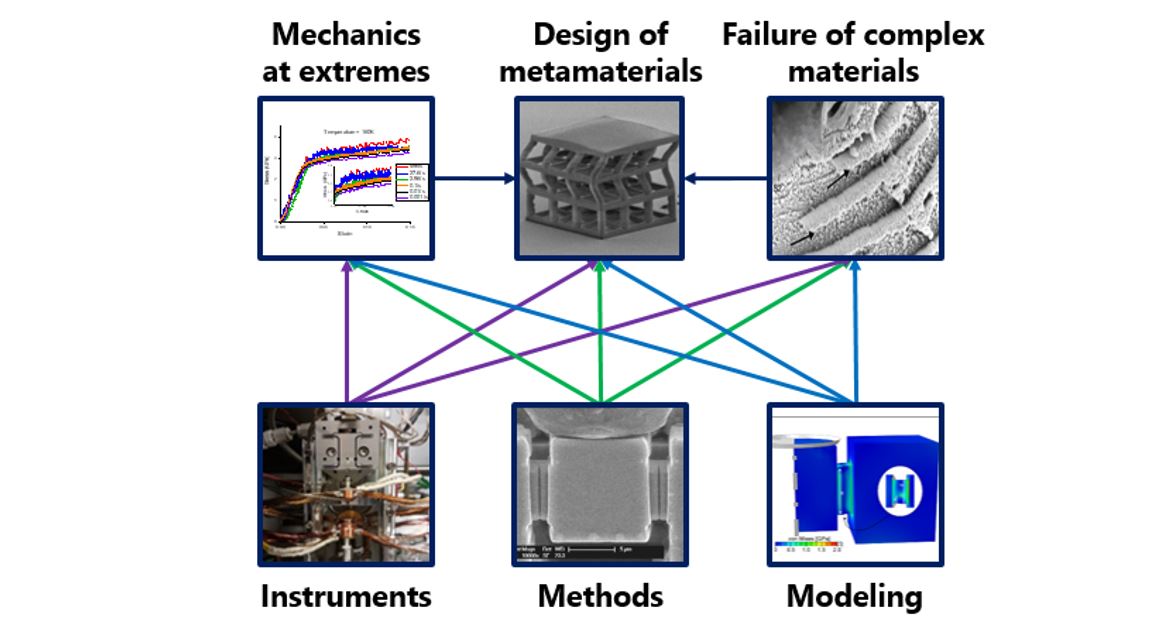

The Architectured Materials Group aims at developing novel ceramic-based materials that fill desirable white spaces in the Ashby diagrams and feature additional functionalities. We investigate fundamental processes of plasticity and fracture under extreme conditions and multiscale toughening mechanisms in complex hierarchical materials. We translate this knowledge into the design of novel porous ceramics, composites, and coatings with hierarchical architecture and tailored microstructure that allow us to combine usually mutually exclusive properties and functionalities. To achieve this, we actively develop scientific instruments and methods and closely integrate experimental and modeling approaches.

Fundamental processes of plasticity and failure in brittle materials

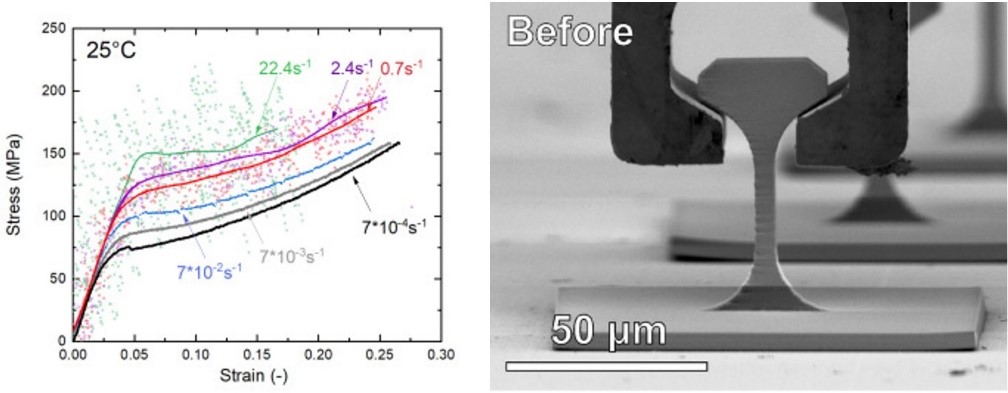

A potential pathway towards high specific strength materials is to make use of both extrinsic and intrinsic size effects. We investigate the fundamental processes of plasticity and fracture at the nanoscale and the effect of grain and component size on the mechanical behavior through a combination of thermal activation analysis, microstructural analysis, and computational modeling. A thorough understanding of the fundamental deformation and fracture mechanisms enables us to find pathways for in-fluencing the mechanical behavior of the material through microstructural design and architecture. To achieve this, we push the limits of what can be measured today through instrument and method devel-opment, e.g. for mode-dependent fracture, variable temperature, or high strain rate experiments. (Acta Materialia 2023, Materials & Design 2022, Materials & Design 2020, JMR 2019, Nano Letters 2019, FFEMS 2018)

Microtensile experiments as a function of strain rate on specimens prepared by 2 photon lithography (Materials & Design 2020)

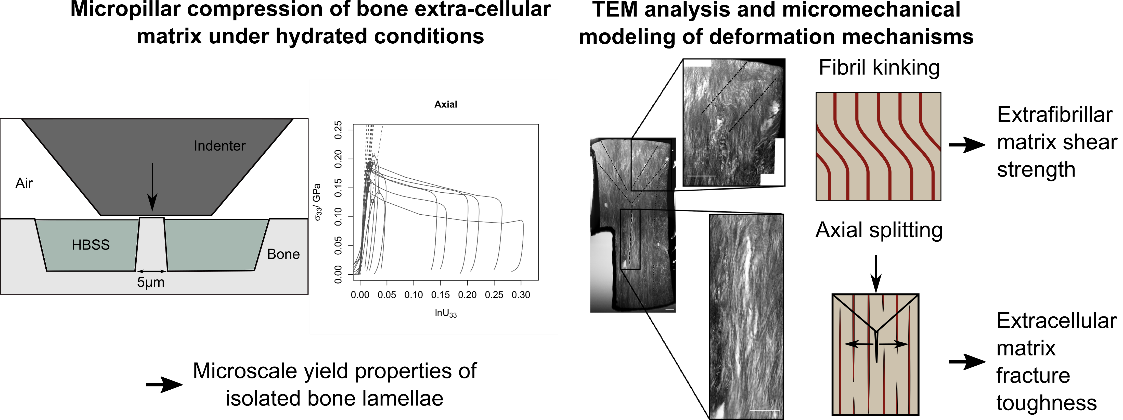

Multiscale failure of hierarchical materials

Furthermore, we study the failure of hierarchical materials such as biological nanocomposites to identify how these materials manage to combine toughness and strength with a light weight through multiscale toughening mechanisms. We assess the influence of their complex microstructure, i.e. the role of interfaces, defects, and material inhomogeneity, on their macroscopic failure behavior. Combining mechanical experiments, microstructural analysis, and mechanical modeling spanning from the nano- to the macroscale allows us to investigate and model the underlying physical processes at all relevant length scales. (Bone 2023, Acta Biomaterialia 2021, Acta Biomaterialia 2020, Acta Biomaterialia 2017, Nature Materials 2014)

Study on the deformation and failure mechanisms in lamellar bone through combination of micropillar compression, TEM imaging, and micromechanical modeling (Acta Biomaterialia 2017)

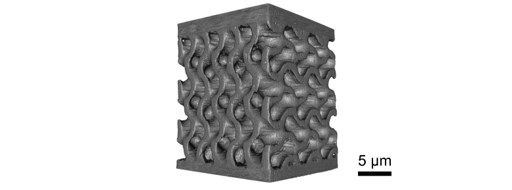

Design, synthesis, and characterization of architecture materials, composites and coatings

Based on the gained knowledge on fundamental processes at the nanoscale and multiscale toughening mechanisms, we develop novel ceramic-based materials that feature advantageous combinations of properties through simulation assisted design. This is achieved by making use of size effects, micro-structural design, and hierarchical architecture through a combination of diverse additive manufacturing and coating techniques such as lithographic and electrochemical methods to prepare materials with unique combinations of properties and functionalities. (Materials & Design 2020)