Nanopowders and ceramics

Within the scope to use materials and energy ressources in the most sustainable manner, attention is put on advanced morphological, chemical and crystallographic characteristics of ceramic powders, materials and composites. Special focus is put on the multidimensional space, beyond density and grain size, and the resulting effects on the materials properties with the aim to tend towards advanced microstructure and grain boundary engineering.

Powder synthesis

Among our competences is the synthesis of functional oxide nanoparticles (by flame processes), their characterisation and processing.

Powders can be used as fillers in polymer composites and coatings, or serve as a starting material for advanced ceramic components. Hereby special focus is put on the particles characteristics such as their shape, size and phase with the purpose to enable the development of materials with new or improved properties. Engineered quality powders are key to achieve innovation with the best performance and added-value of the materials.

We perform R&D collaborations in the frame of national and international projects with partners from industry and university.

Three-dimensional shaping of ceramics

Driven by the remaining challenges in the additive manufacturing field, light-based ceramic shaping is another competence area. Studying the whole process chain, special focus is put into into powder feedstock preparation and slurry formulation. Our goals are not only to shape ceramic parts - and the future - but do so expanding and optimizing their properties.

Current research example:

Shaping of complex shaped, high precision and reliable parts as well as the long processing time and cost-intensive post processing is a key challenge in ceramics processing. Selective laser melting could be a solution of these problems. Although it is already a well-controlled and extensively used technology in the field of metals, alloys and polymers, key problems still have to be resolved for its use on brittle materials, and especially high performance ceramics.

The inability to closely monitor and fine tune the interaction of laser light sources with ceramic based powders remains a problem. Combined with the slow sintering kinetics of ceramics, a whole research field is left to explore. This highlights the current absence of industrial SLS processes to consolidate ceramic powders into dense structures with controlled material properties.

In our research, nanosized ceramic powders are granulated by spray drying to improve the powder handling especially from a flowability and safety point of view. Focus is put on maximizing the powder bed packing density and its influence on the solid and liquid phase sintering. Furthermore, the influence of the composition and morphology of these composite granules on the light absorption is studied, which in addition to minimizing thermal stresses and cracks is a key challenge for the future.

Ceramic based filters and membranes

Filters and membranes play an increasingly important role for technological breakthroughs bringing environmental, societal and economic value. Among other materials, ceramic based ones are in this field important because of their specific properties such as heat or chemical resistance. Hereby we focus in particular on the advanced microstructural control via powder selection and processing as well as advanced doping and sintering strategies.

Current research example: Virus Filtration applying surface modified ceramics and carbon nanotubes

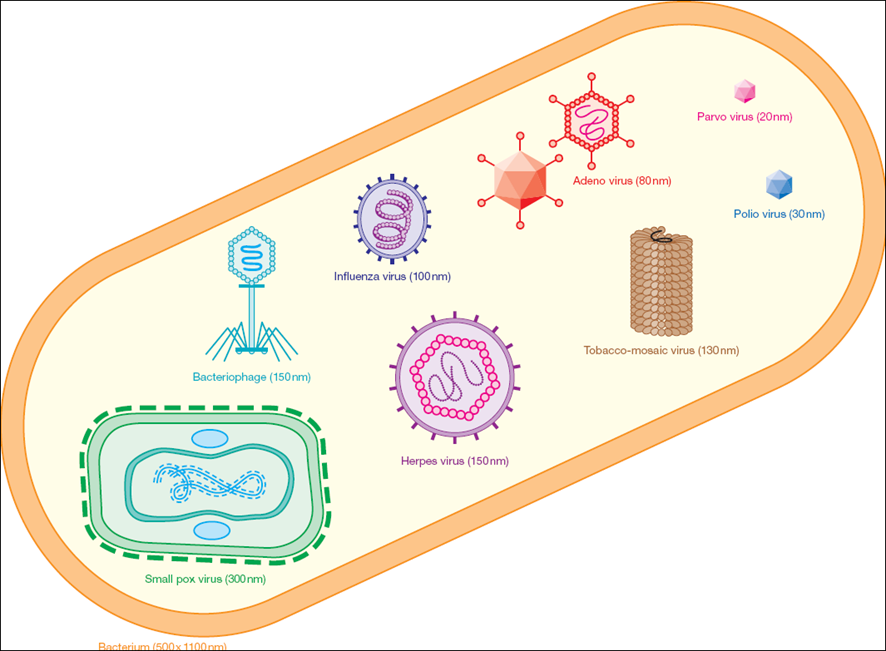

Water purification is necessary to prevent the spread of different diseases, caused by water-borne germs like bacteria, protozoa, and viruses. The germs may be separated from the water by a physical process, where the contaminated water is passing a porous medium like a filter or by adsorption driven separation processes. Our projects are focused on the adsorption based separation of viruses from water applying nanostructured, ceramic based filters as well as modified nanofibers originating from carbon nanotubes CNT and graphene. The biggest challenge results from the required filtering scale, namely the size of the viruses 20-50 times smaller than bacteria.

Recently we could evaluate the application of surface modified ceramic water filters for virus removal. Virus separation efficiencies (MS 2 bacteriophages and PhiX 174 bacteriophages ; size 25 nm, PZC 2 and 7 respectively) of 99 % to 99.99 % could be achieved. Such efficiencies being limited to narrow pH conditions more research is necessary to improve the systems to be compatible with common water sources. Modification of the highly active, porous ceramic surface was achieved by incorporation of nanosized inorganic particles.

As an alternative and promising solution for a broad pH spectrum, we apply CNT based fibers, after modification of the nanostructured surface.