Equipment & Services

Equipment

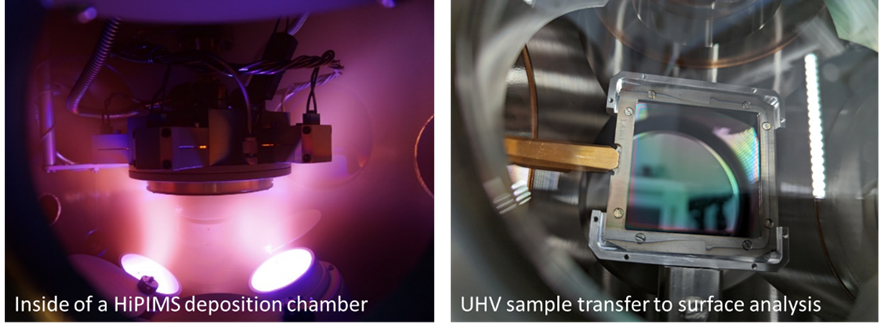

At the heart of our research are our deposition chambers. Here we synthesize thin films and coatings in ultra-high vacuum (UHV) conditions using plasma-based deposition techniques. These processes are scalable and industrially relevant, yet provide ideal prerequisites for the synthesis of exciting new materials, such as previously unreported functional nitrides. Of particular interest for the group are advanced sputtering techniques, such as high-power impulse magnetron sputtering (HiPIMS). Using different synthesis environments, we develop thin films for various applications, such as piezoelectric devices, optoelectronics or protective coatings for use in demanding environments (see also our Research and Projects page).

To better understand and control the synthesis conditions we employ process monitoring as well as plasma diagnostics. To investigate the resulting materials properties we use state-of-the-art materials characterization tools, but also fully custom setups for the automated high-throughput mapping of functional properties. The Coating Technologies Group also operates multiple XPS instruments at Empa Dübendorf. Recently, we established a unique infrastructure for UHV sample transfer between our deposition tools and the surface analysis chambers facilitating meaningful surface analysis on air-sensitive thin films.

Deposition Systems

- AJA ATC-1500 UHV sputter system (shared with Lab203):

- Our work horse for functional thin film development

- Sputter modes: (reactive) DC/RF

- Combinatorial gradients: composition/thickness/temperature

- AJA ATC-1800 custom UHV sputter system:

- Optimized for process development & synthesis of metastable nitrides

- Sputter modes: (reactive) DC/RF/HiPIMS (ionautics, HiPSTER BiPolar)

- Atomic nitrogen source (Oxford Applied Research, HD60)

- Combinatorial gradients: composition/thickness/temperature

- Custom industrial scale HV HiPIMS sputter system:

- Optimized for HiPIMS deposition on large samples

- Sputter modes: (reactive) DC/HiPIMS (Melec, SPIK 3000A)

- Custom UHV sputter system:

- Synthesis of functional thin films in co-planar or confocal deposition geometry

- Optimized for nitride and oxynitrides deposition

- Sputter modes: (reactive) DC/RF/HiPIMS (ionautics, HiPSTER BiPolar)

- Combinatorial gradients: composition/thickness/temperature

Process Monitoring and Plasma Diagnostics

- Hiden EQP 300 (time and energy resolved mass spectrometry)

- Ocean Optics Maya 2000 (optical emission spectroscopy)

- Impedans Langmuir Probe (plasma diagnostics)

- Impedans Semion Retarding Field Energy Analyzer (plasma diagnostics)

- CAU custom passive thermal probe (plasma diagnostics)

Materials Characterization (selected)

- Bruker D8 Discover with 2D detector (structural and phase analysis; XRD)

- Helmut Fischer XDV-SDD (bulk-composition & film thickness; XRF)

- Helmut Fischer Picodentor HM500 (nano-indentation)

- Physical Electronics Quantum 2000 (surface analysis; XPS)

- Physical Electronics Quantera (surface analysis; XPS)

- UHV transfer to our deposition systems possible

- Custom 4pp mapping instrument (sheet resistance mapping)

- Custom UV-Vis & PL mapping instrument (transmittance, reflectance & PL mapping, high-throughput degradation studies under controlled illumination and climatic conditions)

Combinatorial Materials Science

To facilitate the rapid development of new thin film technologies we have developed a comprehensive infrastructure for combinatorial synthesis, but most importantly automated characterization and streamlined data-analysis. All characterization techniques (see above) are capable of fully automated property mapping on combinatorial libraries. In addition, we developed custom instruments for the mapping of functional properties (e.g. resistivity, transmittance/reflectance, photoluminescence) and for accelerated aging studies under operating conditions (more details coming soon). The resulting large datasets are using the CombIgor framework and other custom-written software routines.

Services

In addition to collaborative research projects, the Coating Technologies Group provides services and support not only to academic research partners, but also for industry partner. If you have a research need in the domains of thin film development or surface analysis please get in touch!

-

Share