Conductive Electrodes & Barrier Substrates

Transparent and conductive electrodes

The development of highly conductive and transparent interface materials and their application in organic optoelectronic devices is an important research topic. One challenge is to develop new materials that compete or outperform the commonly used ITO in terms of costs, transparency, electrical resistance and resistance to cracking when bent. Another challenge is that thin films of such materials can be deposited at low temperatures by large-area compatible coating methods on flexible substrates. The development of highly conductive and transparent materials with improved properties will increase the device performance and lower the industrial production costs. Such materials are interesting for organic solar cells, displays and light-emitting devices, and for transparent electronics in general.

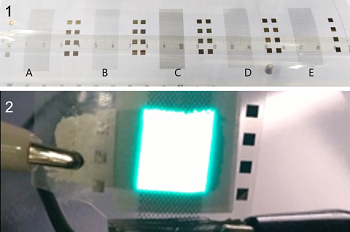

1 Gravure printed metal mesh grids for use as transparent electrodes 2 Electroluminescent device screen printed on grid electrode

Printed Ag-grids electrode

One way to replace ITO based electrodes is by using a high conductive metal grid filled with a transparent conductor. In our lab we realize gravure printed silver grids including a conducting PEDOT:PSS filler layer, printed by screen printing. The following figure shows 5 different grids with varying line thickness and line pitch as well as a electroluminescent built on such grid.

Schneider, R. et al. Int J Adv Manuf Technol (2019) https://doi.org/10.1007/s00170-019-03835-7

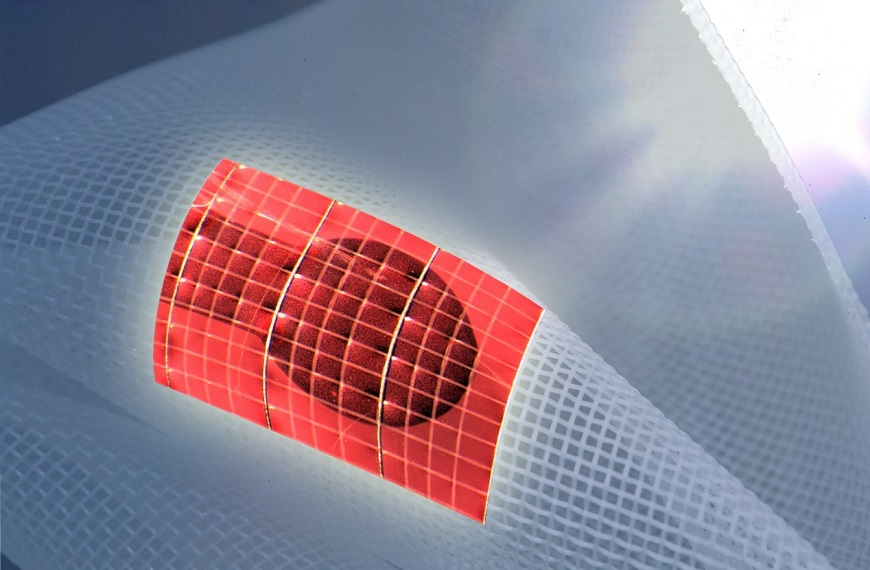

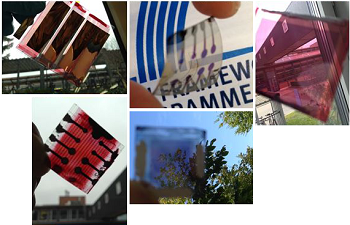

Woven fiber electrode

Together with our industrial partner Sefar AG, we have introduced a flexible, stable and transparent electrode for OPV cells consisting of polymer fibres and current-collecting metal wires woven into a mesh. To provide a stable support for the thin OPV active film (~ 150 nm), the holes in the mesh structure (~ 0.07 mm2) were filled with a curable transparent polymer emulsion in such a way that one side of the fabric was fully embedded in the polymer, while metal wires were exposed by ~ 10-15 micrometers to air at the other side. We fabricated woven fabric/PEDOT:PSS(~ 1-1.5 micrometers)/P3HT:PCBM/Al solar cells. This substrate electrode was further developed and used in the EU project TREASORES.

W. Kylberg et al., Adv. Mater. 2011, 23, 1015 ; W. Kylberg et al., Prog. Photovolt: Res. Appl. 2013, 21, 652 ; R. Steim et al., Appl. Phys. Lett. 2015, 106, 193301 ; M. Makha et al., Sci. Technol. Adv. Mater. 2017, 18, 68.

Partner: https://www.sefar.com

Barrier Electrode Substrates

TREASORES was an EU funded project (FP7 contract number 314068) concerned with the cheaper production of large area organic electronics such as lighting panels and solar cells. This was achieved by developing materials and processes that are compatible with roll-to-roll processing technology, in particular transparent electrodes, barrier foils and encapsulation layers. The project was led by Prof. Frank Nüesch of Empa (the Swiss Federal Laboratories for Materials Science and Technology). The TREASORES project finished in October 2015, but we still greatly benefit from the results and collaborations.

Empa has built-up clean room facilities for lab-scale processing of organic solar cells and modules. For the TREASORES project Empa concentrated on solution-processable organic and inorganic layers coated by spin-coating, doctor-blading and slot-die coating on substrates developed and improved by the TREASORES consortium.

Link to TREASORES http://treasores.eu/

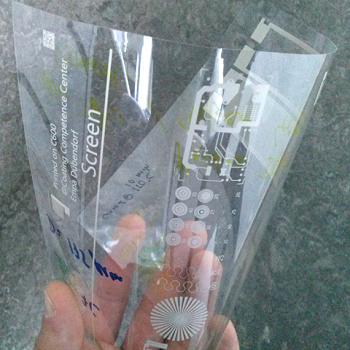

Laminated top electrode for perovskite solar cells

In the CCEM-CH project (CONNECT-PV) we developed flexible and transparent electrodes that can be applied by lamination. We used the lamination process of the top electrode for perovskite solar cells. The laminate electrode consisted of a transparent and conductive plastic/metal mesh substrate, coated with an adhesive mixture of poly (3,4-ethylenedioxythiophene):poly(styrenesulfonate), PEDOT:PSS, and sorbitol.

M. Makha et al., Sci. Technol. Adv. Mater. 2016, 17, 260

Protection Layer for Ultrathin Glass Foils

Ultra-thin glass is a very attractive substrate, as a high performance material it has the potential to substitute various flexible substrates. Key functionalities are excellent barrier properties against water and oxygen, a high thermal stability and a very smooth surface while it is still flexible and highly transparent. Contrasting this, glass is easy to break, which brings difficulties in handling flexible glass.

Glass composite materials can combine advantages of different material types. Goal of the project was to produce laminates of ultra-thin glass and PET foils which allows easier further processing.

The laminates can find applications in technical products where the protection from water and oxygen is essential, e.g. as substrate and encapsulation solution in organic solar cells (oPV) or organic light emitting diodes (oLED). This project was a collaboration of EMPA and the swiss company Folex AG.

Partner: https://www.folex.ch

-

Share