Cable Tests

We conduct fatigue and tensile testing on tendons and stays cable having up to 55 parallel strands and locked-coil cables with and external diameter up to 200mm. The tests are performed according to the client specifications which bases on guidelines such as ETAG 013, EAD 160004-00-0301, PTI, fib Bulletin 30 and others. Our specific testing capabilities are describe in the articles below.

The benefits for you:

- A competent and prompt response to all your testing requirements.

- Cost-effective testing carried out on your behalf by experienced specialists.

- Thanks to our many years of experience we can provide tailored consultancy. We can help you plan and optimize your test cables, including the necessary anchoring systems, right from the initial design stage.

- Thanks to the facilities and experts at our disposal, we can provide interdisciplinary consultancy in the event of incidents of damages.

- Accredited as Laboratory for static and fatigue test.

Large Fatigue Tests

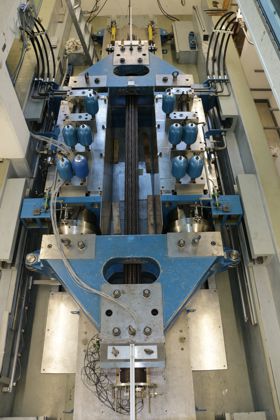

Tensile fatigue tests with large forces are performed in the Large Empa Fatigue Testing Machine (Figure). This testing machine is designed to apply a large por-tion of the lower fatigue load by means of a leaf spring packet. The remaining force required to reach the prescribed lower fatigue load, as well as the fatigue load range is applied by hydraulic jacks (maximum six) driven by four "Amsler"-pulsers.

The Empa Fatigue Testing Machine has the following specifications:

Frequency (not adjustable): 4.4Hz, i.e. Test to 2 Mio. cycles lasts only 5.5 days

Maximum upper load: 6.7MN

Maximum load / displacement range: ~1.6MN, or ~8mm

Length of test sample: 5.5m to ca. 7m

Small Fatigue Tests

Tensile fatigue tests with forces up to 2000 kN are performed in the small Empa Fatigue Testing Machine (Figure).

The Empa Fatigue Testing Machine has the following specifications:

Frequency: adjustable between 1 to 8 Hz

Maximum upper load: 2.5MN

Maximum load / displacement range: ~2MN, or ~5mm

Length of test sample: 3m to ca. 4m

Static Tensile Tests

The tensile static tests are performed in the ELS 1043 testing machine (Figure 4). This machine was developed at Empa to test specimens up to 30 MN. It can ac-commodate cables with lengths between approximately 5300 mm and 7500 mm and is equipped with a pair of low friction hydraulic actuators with a capacity of 15 MN each. These actuators act on two crossheads, which lie next to the bear-ing plates and anchor heads. All parts of the testing machine are mounted on roller gears.

Tests can be carried out in force or displacement controlled mode within the available displacement range.

The Empa Static Testing Machine has the following specifications:

Max. Loading: 30MN

Piston stroke nominal: 120 mm

Max. cable diameter: 250 mm

Max. anchor head size: 600x600 mm

Leakage Tests according to PTI

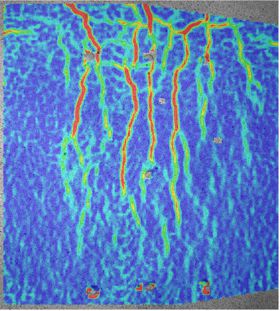

After a fatigue test to over two million cycles, the cable system is submerged in a tank (Figure) in a red dye solution for 96 hours. The subsequent dismantling of the system is photographically documented, and the presence or absence of the red dye solution is used to judge the leak tightness of the cable system.

Consultancy

We provide consultancy for the evaluation and optimization of cables and anchor heads using 3D finite element (FE) computing methods and experimental methods using 3D digital image correlation (DIC) methods.

-

Share