Silica aerogel production concepts

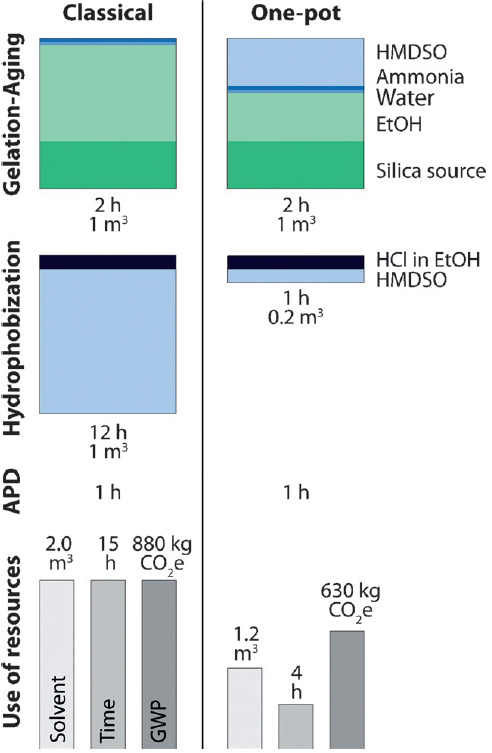

In 2013, a one-pot production process was patented by Empa. This process minimizes the use of solvents and produces silica aerogel granulate by ambient pressure drying within only 4 hours from start to finish. The production process consists of three steps: gelation and aging, hydrophobization and ambient pressure drying. The production process was scaled up in a pilot reactor with a batch volume of 70 L and the aerogel granulate produced by this method has a thermal conductivity of 17.9 mW/(m.K), as low as that of commercially available granulate [1]. Importantly, the new production process substantially reduces production cost, processing time and CO2e emissions during production.

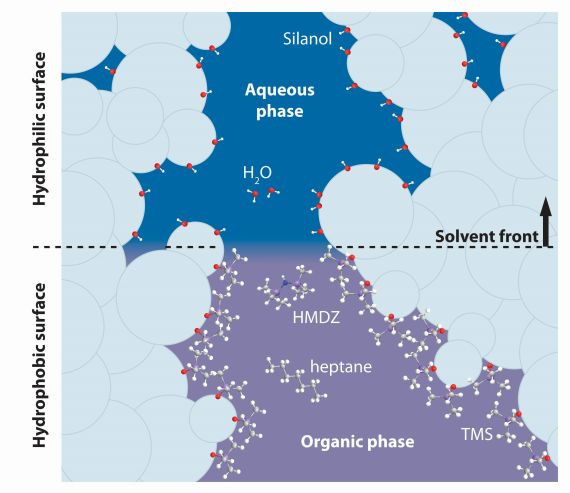

In addition to the work on silica aerogel granulate with its 1-5 mm diameter aerogel particles, we also develop new production processes for fine silica aerogel powders. Here, the small length scales of the gel particles allow for even faster production processes and the use of waterglass as a precursor. Empa holds several patents in the area, particularly on the use of phase transfer agents that promote and accelerate the hydrophobization of the silica gel particles, and we have also published on the fundamental sol-gel aspects of the powder production process [2-3].

-

Share