Thermal transpiration

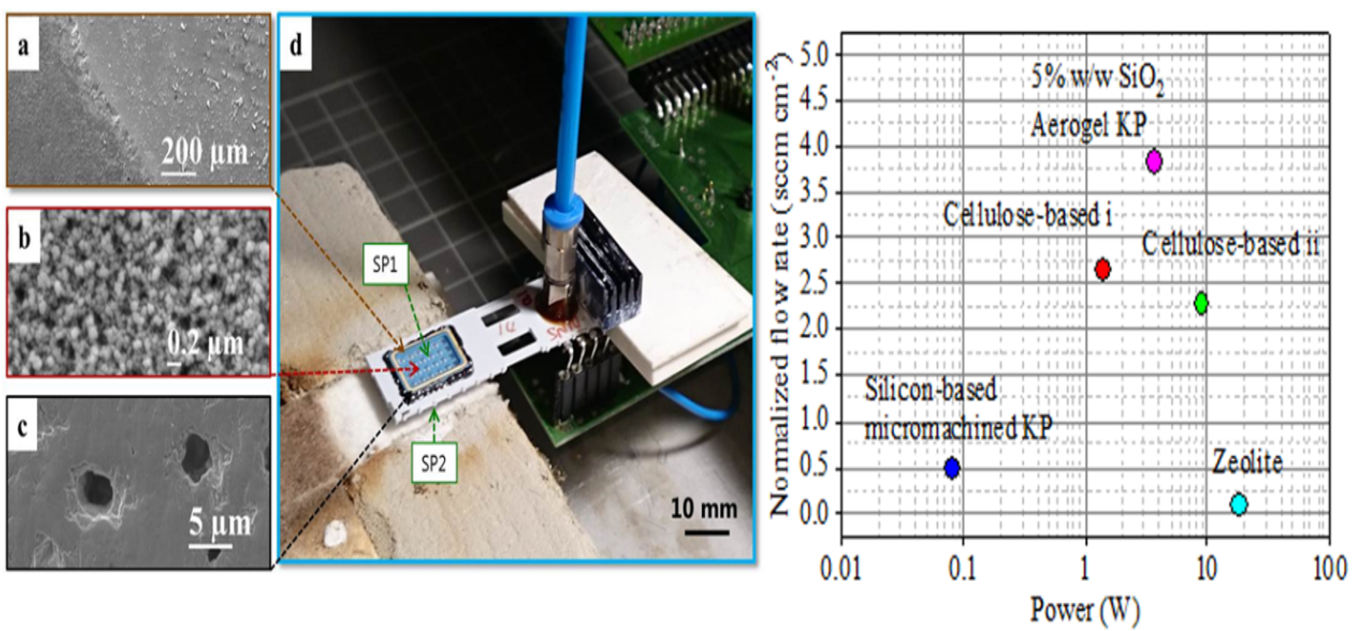

In collaboration with EPFL, we have developed a silica based aerogel Knudsen Pump prototype by combining a low temperature co-fired ceramic technology and sodium silicate based aerogels. A temperature difference applied by resistive heating of the ceramic substrate and a flow rate density ~38 µl min-1 mm-2 was reached. A comparison with other Knudsen pump membranes shows outstanding performance [1].

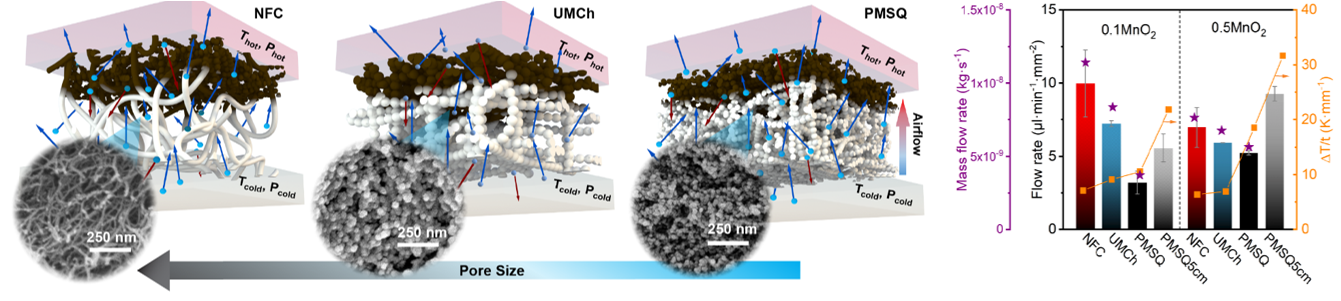

Recently, based on a breakthrough 3D printing technology, our group was able to print a prototype membranes with a top-layer containing manganese oxide nanoflakes. The MnO2 serves as a dual-functional light absorbers for the efficient photo-thermal conversion to reach a pumping flow rate of 20 µl min-1 mm-2, and in addition, the catalytic degradation of VOCs [2]. Furthermore, the processing, pore formation and properties (pumping and catalysis) correlations in an aerogel Knudsen Pump system were explored, and various aerogel materials with complementary properties have been developed [3].

[1] S. Zhao et al., Dimensional and Structural Control of Silica Aerogel Membranes for Miniaturized Motionless Gas Pumps, ACS Appl. Mater. Interfaces 7(33) (2015) 18803-18814. [2] S. Zhao et al., Additive manufacturing of silica aerogels. Nature, 2020, 584 (7821):387-392. [3] S. Drdova, S. Zhao et al.. Biomimetic Light‐Driven Aerogel Passive Pump for Volatile Organic Pollutant Removal. Advanced Science, 2022, 2105819.

-

Share