Liquid-core Fibers

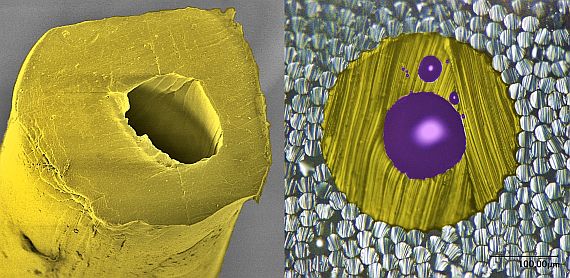

With bicomponent melt-spinning, several functionalities can be combined in one fiber. A new class of liquid-core filaments developed at Empa even further expands the array of possible fiber performance characteristics. We produced liquid-filled polyolefin and polyamide filaments with diameters between 45 and 200 μm and liquid contents up to 25 vol%. To our knowledge, it is the first liquid-core fiber that is in-situ filled with a liquid in a continuous melt-spinning process.

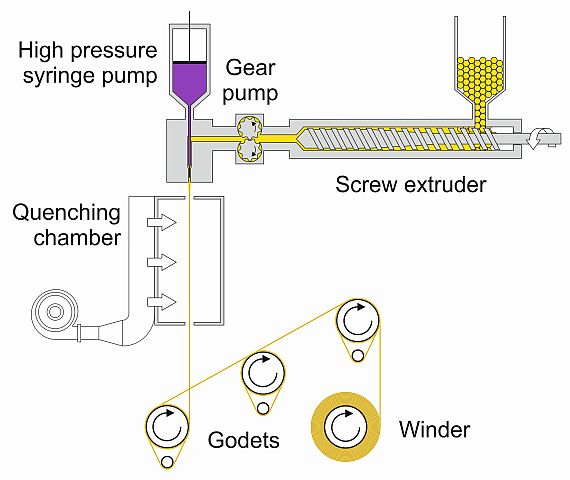

Filling fine hollow fibers with a liquid would become increasingly slow and uneconomic at extended filament lengths. In our setup, the polymer is supplied from single-screw extruder and gear pump, while a high-pressure syringe pump injects the core fluid immediately during production. Leaving the spinneret, the further run of the filament is equal to conventional melt-spinning.

A suitable liquid for the core has to meet several elementary requirements to enable continuous and stable injection into melt-spun filaments: It must exhibit high thermal stability to withstand extrusion temperatures, and relatively low vapor pressure (< 1 atm) at the processing temperature of the polymer sheath to prevent exit spraying.

Liquids in the core of a synthetic filament can provide unprecedented properties to textiles and composites, without compromising mechanical properties, dyeability or washability. So far, we could show that our novel filaments provide promising properties regarding damping, flame retardancy, perfuming and sensing.