Transport at Nanoscale Interfaces

Research Infrastructure

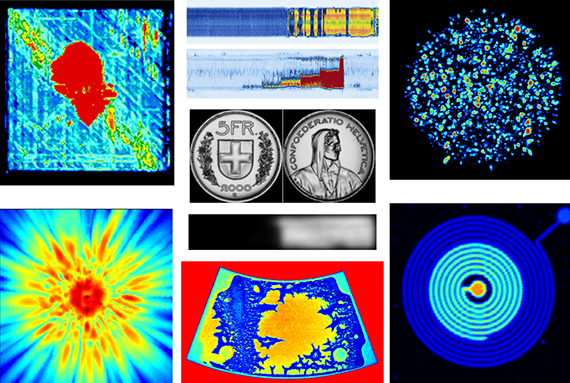

Ultrasonics is a non-destructive evaluation technique for research and application. It allows the localization of flaws, the determination of geometry and elastic properties

- Imaging is done by mechanical scanning single element ultrasonic probes, or, in case of the phased array technique with an electronic steering of ultrasonic waves – enhancing the speed of inspection

- With air-coupling no liquid is required giving access to new fields of application (e.g. wood, water sensitive polymers, aerogels, food, paper)

- The numerical simulation of the ultrasonic wave propagation and interaction with devices containing flaws is essential for understanding the experimental results and improving the experimental setup

Methods

- Localization of flaws

- in base materials

- in joined materials (adhesive sealing, soldering, diffusion bonding, welding)

- Determination of geometry

- Determination of elastic properties

- Simulation of wave propagation

Equipment

- Ultrasonic imaging: liquid immersion technique and air-coupled ultrasound

- Ultrasonic contact technique

- Ultrasonic software: data acquisition and evaluation; simulation of wave propagation

Projects

- Non-destructive quality assessment of polymer tube joints

- Ultrasonic diagnostics of glued timber components

- Ultrasonic read-out for wireless implantable strain-sensor

- Ultrasonic phased array technology applied to the online quality control of manufacture of aluminium stabilized superconductors for the large-scale detectors ATLAS and CMS at Cern

-

Share