Measuring the temperature is vital for the control of many processes. We apply thermal transducers for static and dynamic measurements:

- Wired transducers such as Pt 100 and thermocouples for single point monitoring.

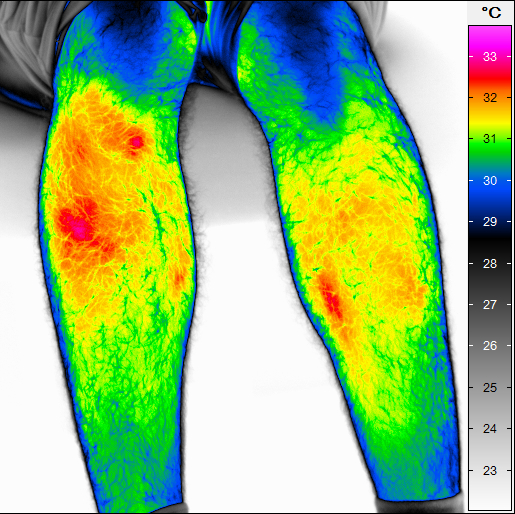

- Thermography cameras for non-contact measurement of temperature fields of object surfaces.

Heating an object in a controlled way allows for the visualization of buried structures and flaws below the surface as well as of the stress state of an object. We apply the following methods of active thermography:

- Pulsed thermography. After exciting the object with a heat pulse the temporal evolution of the temperature field is recorded using a thermal camera. Structures and flaws below the object surface lead to changes in the local cooling behaviour of the surface.

- Lock-In thermography. The object surface is periodically heated by radiation, current or vibration. Depending on the frequency of the heat modulation different depths of the object can be assessed using the surface temperature modulation as well as the phase lag with respect to the exciting source.

- Thermal Stress Analysis (TSA). The object is periodically loaded by a mechanical force. This induces a periodic temperature variation that is proportional to the sum of principal stresses.

Measurements are performed in our laboratory or at the customer’s premises.

-

Share