Alkaline Electrolysis for Renewable Energy Generation: Membrane Development for Industrial Electrolyzers (MEDEV)

Funding: swisselectric research

One of the main components in an alkaline electrolysis cell is the separator or membrane, which is placed between cathode and anode. These separators serve as hydroxide (OH-) conductors, but electronic insulators. At the same time, they prevent the intermixing of hydrogen and oxygen gases produced at cathode and anode, an important aspect not only for gas quality but also for safety reasons. As solid electrolytes with good hydroxide conductivity and sufficient stability at operating conditions have not yet been identified, these membranes usually feature an open porosity which is filled by an electrolytic lye solution, thereby providing the conductivity of OH- ions necessary to promote the electrolysis reaction.

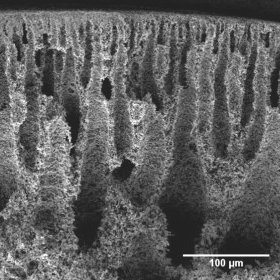

In this project, we develop mechanically and (electro-) chemically stable membranes for operation in high pressure and high temperature alkaline electrolysis (e.g. 30 bar, 100°C, 33 wt% KOH). The main objectives are to tune composition and microstructure of these membranes in order to optimize their performance in terms of ionic conductivity (→ process efficiency) and/ or gas separation properties. This is achieved by investigating the influence of total porosity, pore size distribution, and tortuosity/ effective porosity on zero-bias ion conductivity as well as on gas purity, gas bubble evolution and current—voltage behavior at electrolysis conditions.

-

Share