Development of an in-house recycling process of spent Li-ion batteries: alternatives to established recycling options in compliance with legal and safety requirements

According to the Swiss regulation, it is mandatory for manufactures and importers of batteries to pay an advance-recycling fee and guarantee a proper disposal of the batteries. Thus, KYBURZ plans to establish its own in-house recycling process. This process is both environmentally friendly and cost-efficient in compliance with legal and safety requirements in Switzerland. The role of our group at Empa in the project focus on the chemical characterization of the recovered materials, assessment of environmental impacts and safety implementation of the treatment process. Currently, various dismantling and pre-processing steps of spent Li-ion batteries have been tested at lab scale and the recovered materials have been analyzed and characterized (in particular graphite and metal oxides using EDS, SEM and ICP). Furthermore, the risk of emissions during the recycling process are being assessed.

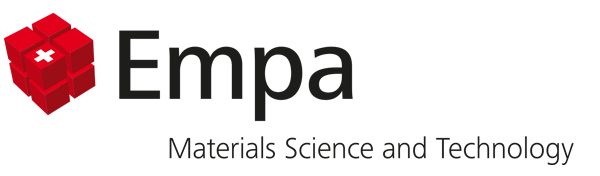

Figure: Discharging and dismantling of a spent LPF battery

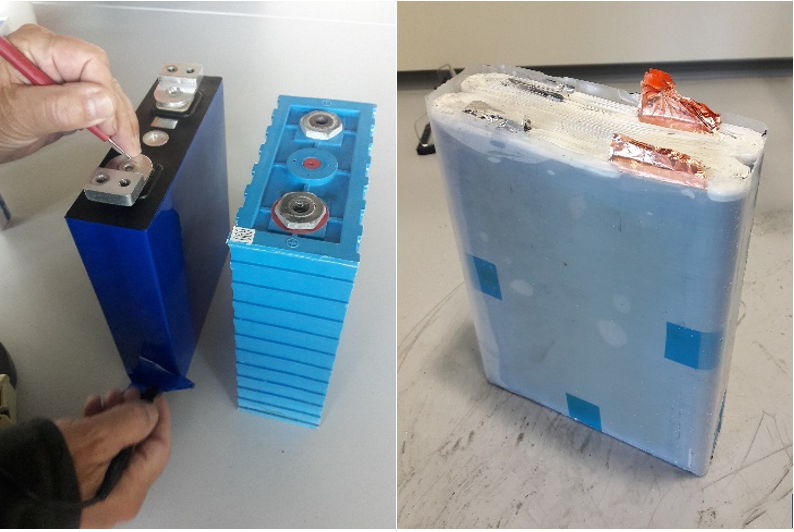

Figure: Recovered materials: a) Aluminum foil b) Copper foil c) Graphite d) Metal Oxide

See also: https://kyburz-switzerland.ch/