The biobattery that needs to be fed

Electric fungi

A battery that needs feeding instead of charging? This is exactly what Empa researchers have achieved with their 3D-printed, biodegradable fungal battery. The living battery could supply power to sensors for agriculture or research in remote regions. Once the work is done, it digests itself from the inside.

Fungi are a source of fascination. This kingdom of life – more closely related to animals than to plants – encompasses an enormous variety. Everything can be found here: from edible mushrooms to molds, from single-celled life to the largest organism on Earth, from disease-causing pathogens to superheroes that produce medicines. Now, Empa researchers have coaxed another ability out of fungi: generating electricity.

As part of a three-year research project, supported by the Gebert Rüf Stiftung as part of their Microbials funding program, researchers from Empa's Cellulose and Wood Materials laboratory have developed a functioning fungal battery. The living cells do not produce a whole lot of electricity – but enough to power a temperature sensor for several days, for example. Such sensors are used in agriculture or in environmental research. The biggest advantage of the fungal battery: Unlike conventional batteries, it is not only completely non-toxic but also biodegradable.

Fungi from the printer

Strictly speaking, the cell is not a battery, but a so-called microbial fuel cell. Like all living things, microorganisms convert nutrients into energy. Microbial fuel cells make use of this metabolism and capture part of the energy as electricity. Until now, they have mostly been powered by bacteria. "For the first time, we have combined two types of fungi to create a functioning fuel cell," says Empa researcher Carolina Reyes. The metabolisms of the two species of fungi complement each other: On the anode side there is a yeast fungus whose metabolism releases electrons. The cathode is colonized by a white rot fungus, which produces a special enzyme, allowing the electrons to be captured and conducted out of the cell.

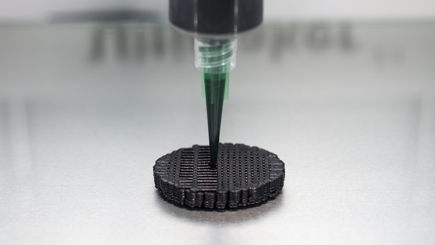

The fungi are not "planted" into the battery but are an integral part of the cell from the outset. The components of the fungal battery are manufactured using 3D printing. This allows the researchers to structure the electrodes in such a way that the microorganisms can access the nutrients as easily as possible. To do this, the fungal cells are mixed into the printing ink. Easier said than done: "It is challenging enough to find a material in which the fungi grow well," says Gustav Nyström, Head of the Cellulose and Wood Materials lab. "But the ink also has to be easy to extrude without killing the cells – and of course we want it to be electrically conductive and biodegradable."

Microbiology meets electrical engineering

Thanks to their laboratory's extensive experience in 3D printing of soft, bio-based materials, the researchers were able to produce a suitable ink based on cellulose. The fungal cells can even use the cellulose as a nutrient and thus help to break down the battery after use. However, their preferred nutrient source is simple sugars, which are added to the battery cells. "You can store the fungal batteries in a dried state and activate them on location by simply adding water and nutrients," says Reyes.

Although the robust fungi survive such dry phases, working with the living materials posed a number of challenges for the researchers. The interdisciplinary project combines microbiology, materials science and electrical engineering. In order to characterize the fungal batteries, trained microbiologist Reyes not only had to learn electrochemistry techniques, but also to adapt them to 3D-printing inks.

The researchers now plan to make the fungal battery more powerful and longer-lasting – and to look for other kinds of fungi that would be suitable for supplying electricity. "Fungi are still under-researched and under-utilized, especially in the field of materials science," Reyes and Nyström agree.

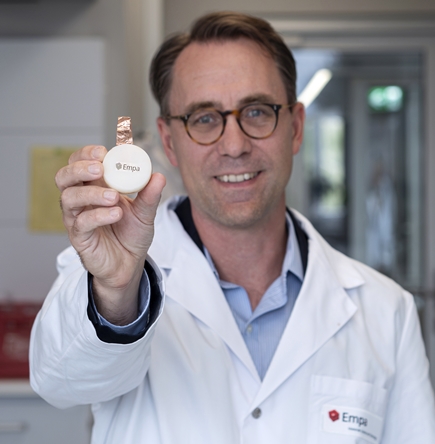

Dr. Gustav Nyström

Cellulose and Wood Materials

Phone +41 58 765 45 83

Dr. Carolina Reyes

Cellulose and Wood Materials

Phone +41 58 765 42 43

C Reyes, E Fivaz, Z Sajó, A Schneider, G Siqueira, J Ribera, A Poulin, FWMR Schwarze, G Nyström: 3D Printed Cellulose-Based Fungal Battery; ACS Sustainable Chemistry & Engineering (2024); doi: 10.1021/acssuschemeng.4c05494

Green technology

Wood is the raw material of the future. It is abundant in Switzerland, is renewable and binds carbon dioxide as it grows. And it is much more versatile than you might think. Empa researchers make wood glow or produce “green electronics” from cellulose fibers, for example environmental sensors or even batteries. They are also analyzing and optimizing the use of wood in Switzerland so that we can use this natural material as sustainably and climate-effectively as possible in the future.

Read the latest EmpaQuarterly online or download the PDF version.

-

Share