Campus co-operate: Topping-out ceremony for the new Empa laboratory building

A specially "upgraded" laboratory building

Empa's future laboratory building, currently under construction in Dübendorf on the new co-operate research campus, celebrated its topping-out ceremony on 14 July. The building will one day house highly sensitive research instruments, among other things. To protect them from vibrations, experts designed and planned the structure accordingly - from massive concrete slabs to the smallest details.

The expansion of the joint Empa and Eawag campus in Dübendorf is progressing fast: On 5 May 2021, construction work began with the groundbreaking ceremony, performed by representatives of the building owners Empa and Eawag, the executing general contractor Implenia Schweiz AG, the architectural firm SAM Architekten and the city of Dübendorf. The next day, excavators drove up and diggings started.

Almost four months later, the laying of the foundation stone took place on 3 September, again by representatives of the partners involved in the project and around 50 guests. On this occasion, a time capsule was placed in the foundation of the new lab building with some items typical of the time as content.

On 14 July, the next milestone was reached: The shell of the laboratory building has been completed and has reached its full height. Traditionally, the topping-out ceremony is then held, at which a small tree is placed on the roof as a clearly visible sign of the completion of the shell. For once, however, the focus of the ceremony is not on the C-level reps of all the companies involved in the project, but on the people who have actually carried out the work, the construction workers. They are thanked by the building owner for their valuable work. A job that presented them with a number of challenges, starting with the preparation of the subsoil.

A low-vibration building for special requirements

High performers are sometimes sensitive; many Empa researchers know this from experience. Whether electron microscopes, with which they examine atoms, or thermogravimetric instruments, with which they "weigh" masses of far less than a microgram: Such equipment must be protected from the tiniest vibrations. Even heavy footsteps in a hallway next door or the rattling of a streetcar on a distant street can falsify measurement results.

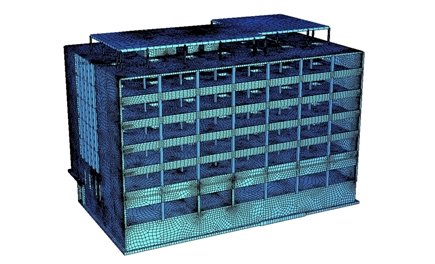

This is a risk Empa is taking into account in its future laboratory building – from its inital planning stage to the completion of the building, which will provide space for around 30 labs and 30 offices as of spring 2024. The requirements for low-vibration buildings are high; they are standardized and described in technical regulations with the help of VC categories (Vibration Criteria), which are also used in micro- and nanotechnology, along with permissible vibration levels.

"VC-C," for instance, is "a suitable standard for light microscopes with up to 1000x magnification," it says in the German version: In the new Empa building it applies to all labs above ground. Stricter VC-E requirements, on the other hand, apply to the area in the basement where the most sensitive instruments will be installed. "Required for equipment of the highest precision," the technical guideline states, "can only be met in a few cases, preferably on floor slabs with no basement."

Between two sources of vibration

Whether or not such specifications could be met at all on the Empa campus had thus to be scutinized in advance. The location seemed unfavorable: a railroad line with heavy trains on the northern boundary and a busy street that borders the site to the south – in future also with a planned streetcar line that will further increase ground vibrations.

In the summer of 2018, specialists from Heiland und Mistler, an engineering firm for structural dynamics based in Bochum/Germany, explored how strongly the ground vibrates and where exactly – with hours of vibration measurements at the ground surface and at a depth of four meters. Moreover, they recorded vibrations in the ground at a nearby streetcar track in Dübendorf to account for this future load as well. And they also registered the magnetic fields at both sites (see infobox).

The results showed that the vibrations at the chosen construction site are basically low enough to meet the strict specifications. "That ultimately makes sense" says Kevin Olas, who is leading the project for Empa, "in the center of the construction site, we're far enough away from both sources."

The question now was: how to build? To ensure that the structure would reliably "swallow" the existing vibrations, two strategies were discussed: The experts advised against a "springy" bearing, for example by means of a foundation on elastomers – because of the complex construction method and possibly a shorter service life. Instead, the option "mass and stiffness" was chosen: You build so heavy and rigid, says Kevin Olas, that vibrations cannot "excite" the building in the first place. "That's ultimately more efficient," says Olas – sort of like an oil tanker that's so massive that even storm waves won't rock it, as structural dynamics expert Dieter Heiland explains.

Large masses and small details

The result is "a super-stiff concrete structure that is almost impossible to vibrate", says Olas, a trained architect – in other words, an extremely heavy structure. This is one of the reasons why 48 piles of a combined pile-slab foundation transfer the loads via skin friction into a more load-bearing soil layer at a depth of up to 18 meters. The concrete slabs are 53 centimeters thick, with seven centimeters of floor screed on top. "From a purely structural point, slabs that thick would not have been necessary," explains Olas.

In the area intended for ultra-sensitive measuring equipment, the floor slab is even thicker, 80 centimeters to be exact. "That's the supertanker within our supertanker, as it were," says Olas. "Almost absurd statically, but for vibration protection, there's just no other way." And under the foundation, there are hard sheets of foam glass instead of compliant polystyrene insulation boards – a detail to ensure an even stiffer deflection behavior.

Apart from trains and automobiles, other influences can also trigger unwanted vibrations. People, for example: In the worst case, even their footsteps can cause problems – but the structural dynamics calculations of the Zurich-based engineering firm WaltGalmarini, which was commissioned, show that the ceilings are solid and stiff enough not to be overly excited by them. Or the ventilation center: Because such systems on the roof can transmit vibrations to the ceilings, they must be "decoupled" with a special spring mounting.

These and many other measures will be hidden from view when the Empa laboratory building is completed in spring 2024. Visitors with an eye for detail will, however, recognize that the building has been consistently designed to minimize vibrations – on the roadways of the access roads: Their surface will be built as smoothly and "quietly" as possible, for example by using a high proportion of air voids to prevent even the smallest vibrations caused by vehicles.

Magnetic field measurements

In addition to vibrations, changes in magnetic fields can also affect the operation of sensitive equipment. The on-site measurements showed that active compensation would be necessary for a scanning electron microscope, for example - for example, by means of so-called Helmholtz coils that generate a homogeneous magnetic field. The main sources of field changes are road traffic on the south side and the railroad line on the north side of the site. In the case of the future streetcar line, the experts expect field changes to be so great that further protective measures will be necessary, such as a compensation cable between the rails, which would significantly reduce the magnetic fields caused by streetcar operation.

-

Share