Personal protection in times of corona

How to assure high-quality masks

Empa researchers have worked with the Swiss textile industry to develop technologies and quality standards for textile masks. Hence so-called community masks can now be produced in Switzerland.

In order to be able to provide Switzerland with effective protective material during the corona crisis, Empa researchers, together with the textile industry and other partners, have been working under high pressure in recent weeks on technologies and quality standards for so-called community masks. Commissioned by the "National COVID-19 Science Task Force" of the Swiss Confederation, the "ReMask" project has now issued specifications for textile masks, which should minimize the risk of corona virus spread.

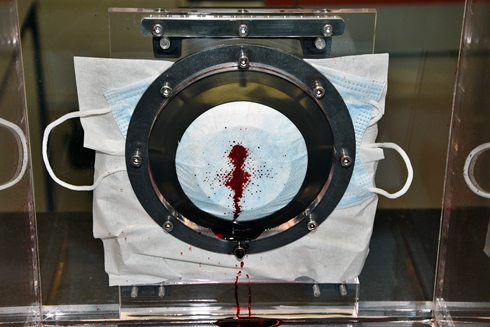

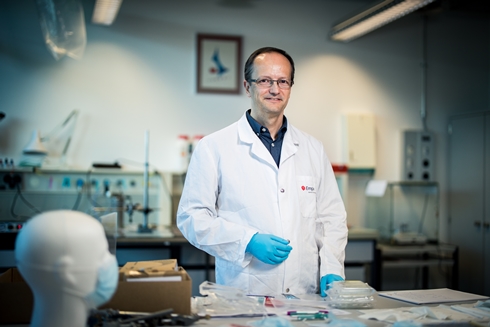

For instance, the "Infection Prevention and Control" expert group of the Science Task Force recently made recommendations regarding quality requirements for community masks. Based on these, Empa has until now tested said community masks during the current crisis. "Within a very short time we have developed and implemented the necessary technologies and processes in our labs," explains René Rossi from Empa's Laboratory for Biomimetic Membranes and Textiles in St. Gallen. In order to avoid the use of hazardous viruses in these experiments, the researchers used artificially stained saliva to simulate what happens in the course of a droplet infection on the inside and outside of a mask. "With the equipment we developed, this situation could be perfectly simulated," says Rossi.

The air permeability (<60 Pa/cm2), splash resistance (impermeable to saliva splashes) and particle filtration efficiency (filtration efficiency of at least 70% for a particle size of 1 micrometer) of textile masks and filter fabrics were investigated. The analysis methods and test protocols for reusable textile community masks are now being transferred to the independent Swiss testing and certification company TESTEX AG in Zurich. Rossi: "We are very satisfied with this successful and extremely fast knowhow and technology transfer."

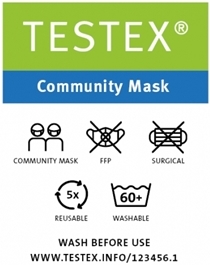

In addition to the tests for reusability, comfort and harmful substances (STANDARD 100 by OEKO-TEX®), TESTEX was able to launch a label for community masks. According to TESTEX, this label offers consumers orientation in the market for textile masks and the assurance of optimum protection in accordance with the recommendations of the Science Task Force.

Empa has also already passed on recommendations for local mask production to various textile companies, including the Herisau-based textile finishing company AG Cilander, Forster Rohner AG, Inter-Spitzen AG and Jakob Schlaepfer AG in St. Gallen, and Schoeller Textil AG in Sevelen, which specializes in high-tech fabrics, Flawa in Flawil, Universal Reusable Packaging GmbH in Tägerwilen, Schips AG in Tübach, LTB AG in Liesthal and Nahtlos in St. Gallen. These companies work together in various consortia. Thus, the production of community masks and textile filters with the required properties according to the specifications of the Science Task Force can start immediately. The companies distribute the products via dealers, but also directly.

"Thanks to the agility and innovative strength of Swiss textile companies, coupled with Empa's know-how, and the award of the TESTEX "Community Mask" label, a milestone has been achieved in the development and production of sustainable protective textiles in Switzerland," says Peter Flückiger, Director of Swiss Textiles. According to Flückiger, the industry association is calling on all manufacturers of textile masks to communicate openly what protection requirements they meet.

Different types of masks

The use of community masks (left) is – as the name suggests – intended for the general public as a way of minimizing the risk of transmission in particular and thus protecting the environment. The textile masks are primarily aimed at so-called source control, which is intended to prevent the spread of viral material from an infected carrier. It is important to ensure adequate protection against liquid droplets of various sizes, which are produced when coughing or sneezing, and against aerosols (particle size down to 1 micrometer). The masks must allow longer periods of wear and be sufficiently permeable to air to minimize breathing difficulties. Community masks do not fall under the certified standards of surgical masks or FFP 1-3 type respirators. The washable community masks should be reusable.

FFP (filtering face piece) respirators are different: FFP masks (pictured left) are designed to protect the wearer from airborne pollutants and pathogens. Dimensions of the smallest particles that can be caught are in the sub-micrometer range. Surgical masks as well as respiratory masks (type FFP) are currently mostly intended to be worn only once.

Images: Cilander, Unsplash, Istock

The ReMask Consortium

ReMask is a national working group, collaborating with the Swiss National COVID-19 Science Task Force (NCS-TF). Their experts support Swiss authorities, hospitals and the industry in their mission to supply hospitals, professionals, and the population in Switzerland with masks of sufficient quality during the COVID-19 crisis. The work is focused on the following tasks:

-

Processing of scientific data to define the optimal conditions for wearing masks

-

Establish national structures and procedures by which the quality of masks, both imported or newly produced in Switzerland, can be measured and reported

-

Propose a contingency plan in case of mask shortage for healthcare professional by enabling them to reuse their masks with minimal risk

-

Supporting Swiss industry in its production of masks against COVID-19 with a verifiable quality label

-

Coordinating in reaching those goals the collaboration of key players across branches including research, medical and industrial sectors as well as Swiss authorities

On March 18, 2020 a group of experts, consisting of MDs, professors, researchers from government and defense laboratories, hospitals, universities, industry and health care from across Switzerland was set up.

This consortium, named “ReMask”, consist of representatives from the cantonal hospital of Winterthur (KSW), the Geneva University Hospitals (HUG), Indema AG, Labor Spiez, Schutz & Rettung Zürich, Rettungsdienst Regio 144 AG (Zürichsee, Oberland, Linth), the Swiss Armed Forces – Armed Forces Staff – Medical Directorate, the Swiss Federal Institute of Technology in Lausanne (EPFL), the Swiss Federal Institute of Technology in Zurich (ETH Zurich), Swiss Federal Laboratories for Materials Science and Technology (Empa), the Swiss society of hospital sterilization SGSV/SSSH/SSSO, the University of Bern (UNIBE), Unisanté, the University Hospital of Basel (USB), the University Hospital of Zürich (USZ), the Valais Hospital (HVS), and industry.

The group was first assembled spontaneously, then joined forces with a task force set up by the Domain of the Swiss Federal Institutes of Technology (ETH Domain), which then was incorporated into a greater national task force. The working group reMask now work with the National COVID-19 Science Task Force (NCS-TF) by supporting its Expert Group 8, addressing Infection prevention and control, as well as other Swiss authorities in charge of the issue such as Swissnoso, the national infection control center. Further information: www.empa.ch/web/remask

Prof. Dr. René Rossi

Biomimetic Membranes and Textiles

Phone +41 58 765 7765

Dr. Peter Wick

Particles-Biology Interactions

Pone +41 58 765 7684

Marc Sidler, Testex AG, Group CMO

Phone +41 44 206 42 68

marc.sidler@testex.com

Burghard Schneider, AG Cilander, CEO

Phone +41 71 353 32 60

b.schneider@cilander.ch

Emanuel Forster, Forster Rohner AG, Geschäftsleitung

Phone +41 71 243 15 15

e.forster@forsterrohner.com

Dagmar Signer, Schoeller Textil AG, Marketing Communications

Phone +41 81 786 08 35

dagmar_signer@schoeller-textiles.com

Dr. Damien de Courten

Indema AG, Swiss National COVID-19 Task Force

damien.decourten@indema.ch

Dr. Michael Hagmann

Empa, Communication

Phone +41 58 765 45 92

Michael.hagmann@empa.ch

Urs Bünter

Empa, Coordination of Media Inquiries

Phone +41 58 765 7602

urs.buenter@empa.ch

Mirjam Matti Gähwiler

Swiss Textiles, Communication & PR

Phone +41 44 289 79 42

Due to the time-critical work in our laboratories, we currently ask you not to contact our researchers directly.

Forster Rohner AG / Schoeller Textil AG / Serge Ferrari AG:

- Webshop for companies

- Webshop for private customers (via Jakob Schlaepfer AG)

High-res images download here

TESTEX AG has already launched a quality label for community masks.

| Audio |

Radio program on Radio1 of May 15, 2020 in German

| Audio |

Radio program on SRF1 Espresso of August 28, 2020 (in German).

| Video |

-

Share