Building smarter

Heat storage in the deep

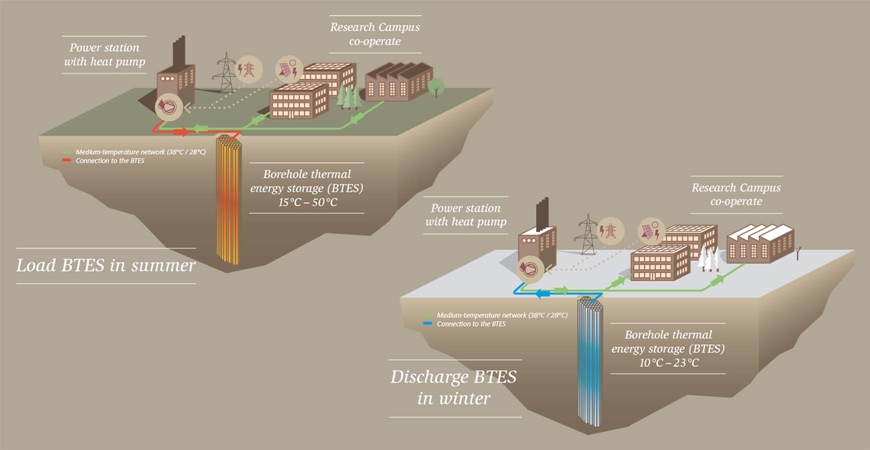

The new, future-oriented research campus, co-operate, in Dübendorf, is itself an object of research. This is because an experimental, seasonal energy storage facility is being built under the site, which will supply energy not only to the new buildings but to the entire Empa campus. In summer, for example, the waste heat from ventilation systems and laboratory equipment will be stored to be used in winter for heating or for the production of domestic hot water. The aim is to either use around 90% of waste heat directly or to store it temporarily in the ground storage facility. In this way, Empa aims to reduce the CO2 emissions of its buildings to a minimum and thus make a huge step towards a sustainable energy future.

Maximum temperatures of 50°C

Empa will be able to use the heat storage facility for research purposes for a period of ten years. The heat reservoir – a field of geothermal probes with a temperature gradient – comprises 144 probes extending up to 100 meters deep into the ground. At this depth, the storage unit works particularly effectively, losing only a small proportion of the stored heat to the environment. In the center of the geothermal probe field, the maximum temperatures can reach 50°C, at the edge the values are around 10°C. A tube system makes it possible to control each tube of the geothermal probe individually or to control defined areas and thus achieve the optimum mix between temperature, efficiency and energy storage.

Although such an earth storage system is very effective, it is also sluggish due to its large mass. The Empa researchers assume that the final operating temperature will be reached after about three to four years.

Climate friendly building

Insulation from empty bottles

>>>>

Empa Zukunftsfonds

Materials to protect the climate

The latest example is a research project on prestressed high-performance concrete, which can now be started thanks to funding from the Ernst Göhner Foundation.

>>>>

Material cycle

Demolition and breakthrough

The new NEST unit Sprint sets standards for circular construction: In just ten months, flexible, COVID-19-compliant office spaces were built using mostly reused materials and components. Sprint demonstrates: The „stockpile” of reusable materials and the re-use potential in the construction industry is enormous – you just have to use it.

>>>>