Photovoltaics

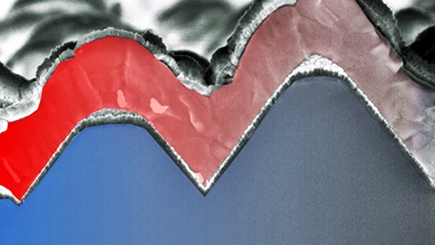

Crystalline light catchers

As a further variant, so-called thin-film solar cells have emerged, which are about 100 times thinner than crystalline silicon cells. This cell structure is flexible and can be vapor-deposited onto flexible substrates such as plastic films or metal foils. The thin-film cells made of the semiconductors gallium arsenide (GaAs), cadmium telluride (CdTe) or copper indium gallium sulfur selenium (CIGS), which have been known for some time, have now been joined by a new class: organic-inorganic perovskites. The term perovskite describes the common crystal structure of the materials in these thin films.

The interesting thing is that perovskites can not only be used as solar cells, but conversely can also serve as illuminators or as a basis for photodetectors, for example in X-ray devices or sensors for smartwatches. For this reason, this class of materials is currently attracting a lot of research activity worldwide. But there is a problem: Many of these perovskite crystals contain so-called organic ions as building blocks. These are crystal building blocks that contain carbon, nitrogen and hydrogen. They melt and evaporate at much lower temperatures than silicon or GaAs, CdTe or CIGS. As a result, many well-proven production methods are not well-suited for these materials.

Industrial manufacturing

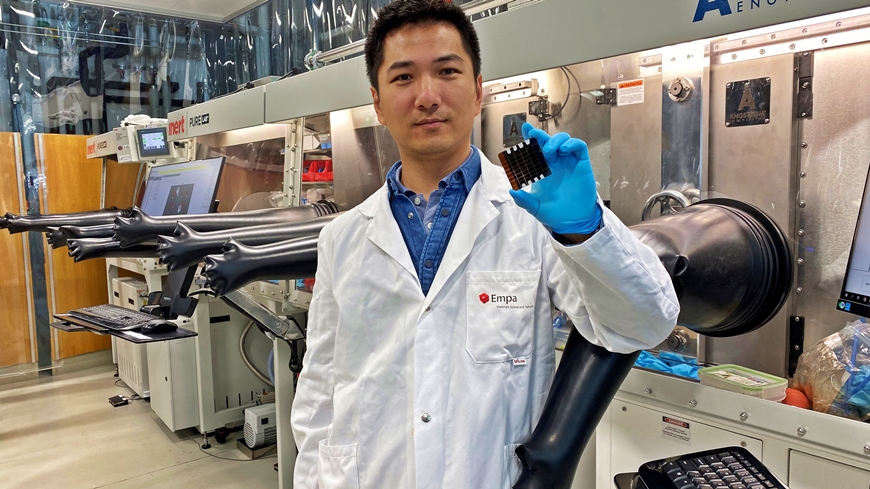

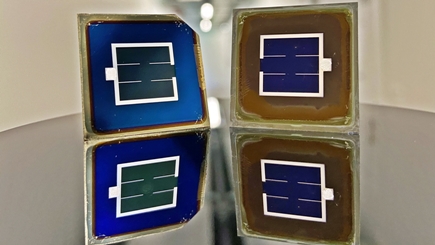

The tasks of the research partners are carefully distributed: Perovskite specialists Ayodhya N. Tiwari and Fan Fu's team from Empa's "Thin Films and Photovoltaics Laboratory" is looking for a flexible perovskite photodetector and solar cells; Chih-Jen Shih's team from ETH Zurich's Nanomaterials Engineering Research Group wants to build perovskite LEDs that produce light with particularly high color accuracy. And Christophe Ballif of EPFL and his team are on the hunt for particularly efficient tandem solar cells that consist of silicon on the bottom and a semi-transparent perovskite layer on top.

All the researchers have already done preliminary work: The EPFL team set a new world record in July: EPFL solar cells made of thick, crystalline silicon with a thin layer of perovskite on top achieved more than 31 percent efficiency. Such a value has already been achieved with other semiconductor cells, but these are about a thousand times more expensive to produce. So this opens a gateway to low-cost photovoltaics. "We have developed a two-step process to apply the organic ingredients of our perovskites gently and homogenously, on medium sized solar cells" explains Christian Wolff, who works on the EPFL team. "We now want to extend this process to a newly developed dry vapor-based method, which will enable to homogeneously cover even larger areas on the one hand, and at the same time see if there aren't even better chemical combinations."

Sebastian Siol at Empa is helping him with this. He is a specialist in coating processes and in the analysis of industrially produced thin films. He will use automated high-throughput experiments to screen a large number of different chemical compositions and process parameters with the goal to create a "library" of promising perovskite mixtures. This will give Wolff and his colleagues in all working groups crucial tips on where to look. That speeds up the journey to the goal of cheap, stable and large-area optoelectronic devices with a manifold of applications.

Non-toxic solvents

Sensors for smartwatches

Fan Fu has a second project that he is pursuing as part of AMYS: Perovskite cells could potentially also serve as photodetectors in cameras or X-ray detectors for medical imaging - and would have two key advantages: they are far cheaper and easier to produce than the silicon camera chips commonly used today. And they are flexible and can adapt to body shapes. Fan Fu uses an example to explain how interesting this could become: "Blood oxygen and pulse rate sensors in smartwatches are partly based on optical detection of blood flow." With flexible, optical sensors, such readings could be obtained much cheaper and at the same time more accurately in the future, says Fu. "Measurement devices that rest directly on the skin are a key technology for future interaction between humans and machines."

-

Share

|

Eye on the process |

|

Pierangelo Gröning, President of the Advanced Manufacturing Technology Transfer Center Alliance and Empa's Research Commission and member of Empa's Directorate, explains the research institute's role in AM research. |

|

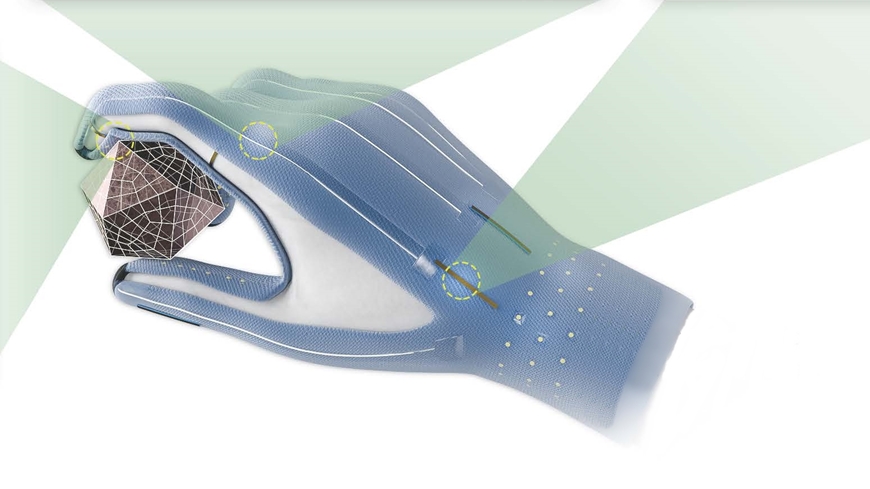

Printed VR glove |

|

An Empa team is developing next-generation VR gloves that will make virtual worlds tangible. The tailored glove is produced largely automatically – using a 3D printing process. |