Accelerating research

Developing multifunctional coatings 50-times faster

The "Empa Zukunftsfonds" seeks private donors for outstanding research projects that are not (yet) supported elsewhere. For example a project from Empa's Surface Science and Coating Technologies laboratory: With the support of the Helmut Fischer and Anni Walther Foundation the researchers aim to accelerate the development of multifunctional thin films, which could be applied in electronic devices or high-performance optics.

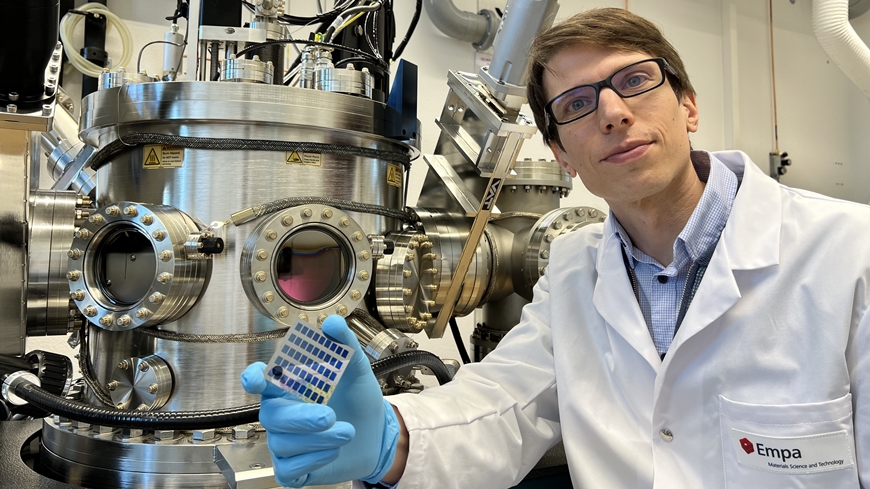

Experiments in ultra-high vacuum deposition systems are often time-consuming and expensive. But what if, instead of 50 experiments, you only had to perform one – and yet still got 50 different material samples? And what if you could automate the characterization of these samples and have the results immediately available for evaluation in a database?

The Coating Technologies Group around Sebastian Siol is pondering these very questions. The answer is obvious: It would be possible to develop novel thin film materials and coatings much faster. For a few years now, Siol's group has been building the infrastructure to make this dream a reality. In a project funded by the Helmut Fischer and Anni Walther Foundation, this technology is now being further expanded and used for the development of multifunctional ceramic thin films.

The "Empa Zukunftsfonds", Empa's fundraising unit, established a first contact with the foundation, which shares the interest in research on multifunctional coatings: The donor has been developing intelligent solutions in the field of film thickness measurements on different materials for 70 years. The foundation therefore agreed to finance a dissertation on this topic and also to expand the group's infrastructure for automatic characterization to include a hardness tester for thin films.

Research into multifunctional thin films is highly complex and time-consuming, as coatings today have to meet increasingly stringent requirements. At the same time, the number of layers is to be reduced. To achieve this, researchers often have to simultaneously optimize several properties that are difficult to combine, for example in coatings with high hardness and low reflection.

But back to Sebastian Siol's dream. Through so-called combinatorial thin film development, his team fabricates layers with controlled gradients using special deposition processes. In this way, large parameter ranges are covered in a single experiment, for example with regard to processing temperature or chemical composition. The resulting layers are subsequently analyzed automatically.

Accelerating research by this kind of high-throughput technologies are key to future materials development. Computers are now predicting new materials with promising properties at an ever increasing rate. However, it is challenging to fabricate and study each one individually. A comprehensive infrastructure for combinatorial materials development could speed up this process significantly. Thanks to funding from the Helmut Fischer and Anni Walther Foundation, the Empa team is a big step closer to this ambitious goal.

Dr. Sebastian Siol

Surface Science & Coating Technologies

Phone: +41 58 765 4380

Dr. Lars Sommerhäuser

Surface Science & Coating Technologies

Phone: +41 58 765 4787

-

Share

|

An iridescent 3D ink |

|

Empa researchers developed a cellulose-based ink that allows to 3D print biodegradable sensors and displays and changes color when heated or stretched – without the addition of any pigments. |

|

An iridescent 3D ink |

|

Empa researchers developed a cellulose-based ink that allows to 3D print biodegradable sensors and displays and changes color when heated or stretched – without the addition of any pigments. |