Making Switzerland more competitive

The innovation accelerators

Innosuisse, the Swiss innovation promotion agency, supports research-based innovation to strengthen the international competitiveness of Swiss industry. In Innosuisse-funded projects, companies work together with universities or research institutes such as Empa to bring innovative ideas to the market. Empa is currently involved in around 80 such projects. Here are four of them.

ComfyPAS: Crystal protection for satellites

On their journey from the Earth's surface into orbit, satellites are exposed to enormous forces – a challenge for the high-tech devices, which often contain highly sensitive instruments. The biggest issues are not caused by the strong acceleration during the rocket launch, but by dynamic loads. These occur primarily during separation events, when spent fuel tanks or the payload fairing are jettisoned via a controlled detonation of small explosive devices. The structure to which the satellite is attached, the so-called payload adapter, transmits the vibrations to the satellite itself. Together with the Swiss space company Beyond Gravity, Empa researchers Marco Ravasi and Andrea Bergamini are working on a new type of payload adapter designed to reduce hazardous vibrations. They are using so-called phononic crystals for this purpose. "Depending on their structure, crystals can reflect, scatter or diffract light in very different ways," explains Bergamini, research group leader in Empa's Acoustics / Noise Control laboratory. Phononic crystals use this particular property of crystal structures – just for sound waves instead of light. With the right structure, the harmful vibrations can be reflected or attenuated in such a way that they no longer pose a threat to the sensitive payload.

Greenpeel 2.0: Turning wood into leather

Vegan leather alternatives often rely on polyurethane, a plastic typically made from petroleum – not exactly the most environmentally friendly solution. Although some renewable alternatives exist, they are not yet fully convincing. Together with the Swiss start-up BINOVA AG, Empa researchers are working on a sustainable vegan leather that can match the original. It should be robust and hard-wearing, have an elegant look and feel and be based on renewable materials as much as possible. To achieve this, the project partners utilize two natural polymers: cellulose and lignin. Cellulose, the basic building block of plant cell walls, is the most abundant biomolecule on Earth. Lignin, one of the main components of wood, is also available in large quantities: It is a by-product of paper production, which is largely incinerated today. Empa researchers led by Gustav Nyström, head of Empa's Cellulose & Wood Materials laboratory, in collaboration with their industrial partners, now want to use these abundant, renewable raw materials to develop a leather alternative that emits up to 80% less CO₂ and uses up to 90% less water than real leather.

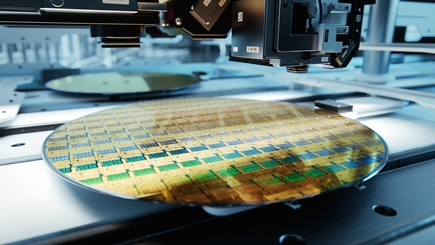

Three Free: No lead, no cry

Few fields demand such high precision as the semiconductor industry. The tiny computer chips and other components are manufactured under extreme conditions. Depending on the process step, temperature extremes, vacuum or strong acids are involved. To ensure proper conditions at all times, they are monitored by various sensors, which in turn have to withstand the adverse environments. This is a challenge for suppliers to the semiconductor industry, such as the Swiss company Inficon AG, which manufactures highly sensitive vacuum sensors, among other things. The manufacturer uses a particularly resistant glass to connect the sensor components. However, with increasing EU regulations restricting dangerous substances, the lead-containing glass was suddenly no longer available. The search for alternatives on the market was unsuccessful, so Inficon approached Empa. In cooperation with the company, Empa researchers led by Gurdial Blugan from the Laboratory for High Performance Ceramics succeeded in developing a lead-free glass that fully meets the high demands. At the same time, the researchers have devised new methods to precisely characterize the new lead-free glass. Following the successful completion of the first project, the partners have already started a follow-up to make the high-tech glass even better.

MalCoFil: A mosquito net with anti-malaria effect

The mosquito is the deadliest creature on earth. Every year, over 600,000 people worldwide die from malaria alone, which is transmitted by mosquitoes. The best protection against infection is provided by impregnated mosquito nets. However, the dangerous Anopheles mosquito is now resistant to many common insecticides. Empa researchers are therefore working together with Swiss companies Vestergaard Sàrl and Monosuisse AG on new types of mosquito nets that effectively kill mosquitoes. In future, the nets should retain their insecticidal effectiveness for years and thus decimate the mosquitoes particularly efficiently. This is achieved using innovative core-sheath fibers which, due to their composition and manufacture, contain new effective insecticides inside them. Empa researcher Edith Perret from the Advanced Fibers laboratory in St. Gallen is confident: "The two-component fibers will enable the production of a new generation of mosquito nets with effective malaria protection." First field studies in Africa with the new netting materials are planned for next year.

Technology transfer

How do innovations get out of the lab and into the wider world? There are different ways, summarized under the term technology transfer. At Empa, technology transfer takes many different forms – be it through direct industry cooperation, Innosuisse-funded projects or by founding start-ups. If these endeavours are ultimately successful, they result in innovative products and solutions that make our world a little bit better.

Read the latest EmpaQuarterly online or download the PDF version.

-

Share