"Impact Award" for Empa Project

A liquid approach to solid-state batteries

The University of Geneva presents the first "Impact Award" to a project by researchers from Empa and the University of Geneva, among others. They were honored for a newly developed method of integrating a closo-borate electrolyte more efficiently into a solid-state battery, which not only ensures greater safety but also higher battery performance.

The technology transfer office of the University of Geneva – Unitec – celebrates its 20th anniversary this week. As part of an anniversary celebration, Unitec presented an award for the invention of the year. The recipients of this new “Impact Award” are researchers from Empa and the University of Geneva for their newly developed method of integrating an electrolyte made of closo-borate into a sodium solid-state battery that had also been newly developed by the team. Solid-state batteries are regarded as a promising solution for the future: They can be charged faster, store larger amounts of energy and guarantee higher safety.

Good, but not yet perfect

From solid to liquid and back

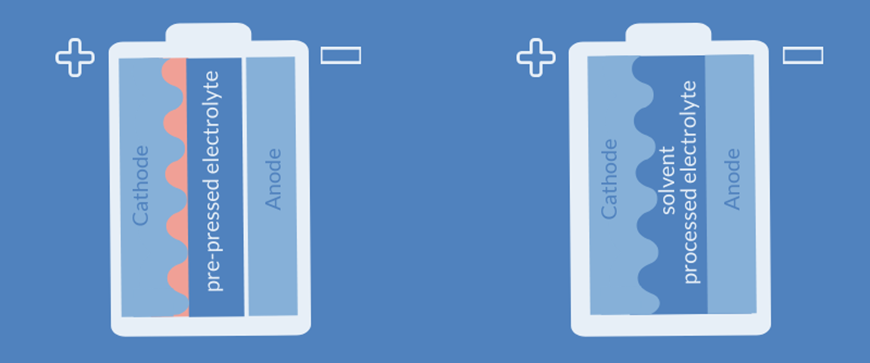

Empa scientist Léo Duchêne and his colleague Romain Moury from the University of Geneva solved this problem by developing a new method to insert the electrolyte practically "seamlessly" between the anode and cathode. The closo-borate salts are dissolved in a liquid and "poured" between cathode and anode. This is followed by drying, in which the liquid evaporates and only closo-borate particles remain, which – in solution – are able to penetrate even the smallest irregularity in the cathode. This ensures continuous contact between the individual layers of the battery and increases its performance.

The inventors are now being awarded the "Impact Award" for this innovative process. "This award is a sign that we are on the right track with our research," says Duchêne. "But there's still a lot to do." The team is currently working on further improving the sodium solid-state battery with the aim of making it even more efficient so that it can succeed in the market.

Léo Duchêne

Empa, Materials for Energy Conversion

Phone +41 58 765 60 94

leo.duchene@empa.ch

Arndt Remhof

Empa, Materials for Energy Conversion

Phone +41 58 765 43 69

arndt.Remhof@empa.ch

Prof. Hans-Rudolf Hagemann

University of Geneva, Dept. of Physical Chemistry

Phone +41 22 37 96539

Empa : Léo Duchêne Ruben-Simon Kühnel, Arndt Remhof, Corsin Battaglia

University of Geneva: Romain Moury, Hans Hagemann

-

Share