New center for AM in medical technology

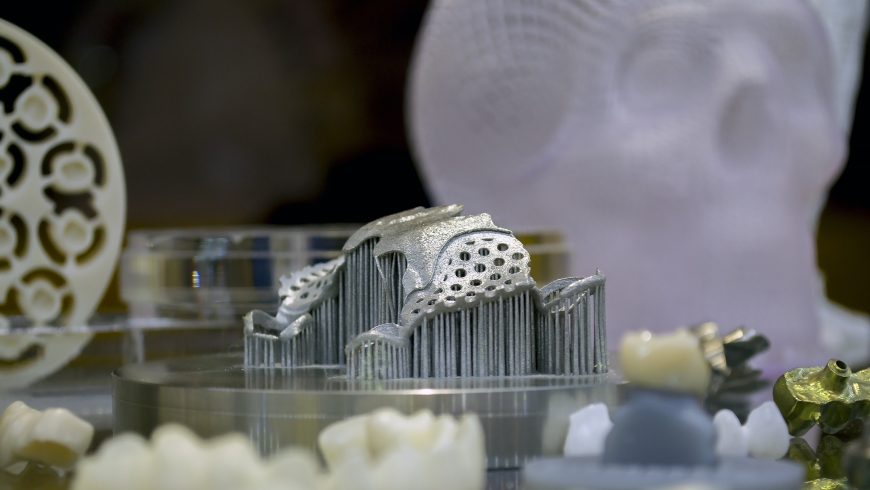

Implants from the 3D printer

3D printing is finding its way into industrial manufacturing. This technology and the increasing digitalization of design and manufacturing processes – keyword "Industry 4.0" – will also play a central role in medical technology in the future. A new technology transfer center in the canton of Solothurn will help to transfer know-how from science to industry – and at the same time accelerate research.

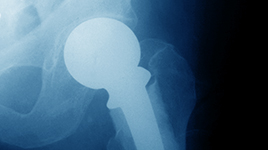

Additive manufacturing, also known as 3D printing, is becoming increasingly important in industry and science. Its great advantage is that complex shapes can be created using a digital model and that individual pieces can also be produced economically. This makes the production method extremely interesting for medical technology. Because every body is unique - so what could be more logical than, for example, printing an implant to measure?

But additive manufacturing is a complex task - especially in the medical field. It requires a great deal of specialist knowledge, for example about the materials used, the manufacturing process and the post-processing of the printed parts, the software used in the design and manufacture of the implant, as well as about the human body and the surgical procedure. In addition, there are legal issues, not to mention the high costs of such a system - especially since the manufacture of medical devices must be validated and run according to a certified process. For many Swiss SMEs in the medtech sector, the obstacles are currently too great to venture into this new world. However, they risk losing their competitive edge in the international competition.

From laboratory to industry

This will change in the future: A new center for the transfer of new manufacturing technologies for medical applications to the medtech industry is being built in Bettlach in the canton of Solothurn. The center, called "Swiss m4m Center", is not a research institute in the true sense of the word, but is intended to serve the transfer of knowledge and technology. "In order to successfully transfer new technologies to industry, the experience of industry on the one hand and new materials and findings from research on the other are necessary. The challenge is to bring both together. This is precisely what we want to achieve with the new center in an important sector for Switzerland, medical technology," explains Pierangelo Gröning, member of the Empa management and initiator of the "Swiss m4m Center".

The new center will house facilities for manufacturing implants and other medical devices using the same manufacturing processes as industrial production. This should close the gap between research and industry. Both companies and research institutions can book and use the center's infrastructure and services. The center will be set up in the form of a public-private partnership and will be financed and operated by both public funds and private companies. It involves the cantons of Berne and Solothurn as well as numerous partners from research, hospitals and the private sector. The latter include the Bettlach medtech company 41medical, on whose site the center is being built. The center is scheduled to go into operation at the end of 2019.

More centers in the planning

Technology transfer centers with pilot production facilities, which are used equally by research and industry and are intended to advance Switzerland as a location for innovation, are a plausible idea. The "Swiss m4m Center" will therefore not be the only one in Switzerland: In order to close the gap in technology development between research and industry and maintain Switzerland as a modern, high-quality production location in the long term, the Alliance for Advanced Manufacturing Technology Transfer Centers (AM-TTC for short) has been set up. It is part of the federal government's "Digitization" action plan and aims to operate a network and an alliance of technology transfer centers that offer open access to their respective infrastructures. To date, in addition to the "Swiss m4m Center", eleven other centers are being considered and planned. The topics range from the manufacture of battery cells to the use of digital manufacturing technologies and robots in the construction industry.

Into the future with 3D printing

3D printing offers tremendous benefits for many industries - and exciting challenges for researchers. Empa is therefore further expanding its leading role in additive manufacturing technologies. In addition to the "Swiss m4m Center" and the "Coating Competence Center" opened in 2016 on the Empa campus in Dübendorf, which houses various 3D printing systems for research purposes, a competence center for additive production of metallic alloys is currently being built in Thun.

Info event

On 19 February, interested individuals and companies will have the opportunity to learn more about the "Swiss m4m Center" and 3D printing for patient-specific implants. Experts will explain the state of the art and the possibilities of additive manufacturing of metallic materials for medical applications.

Location: Old hospital, Solothurn

Date: Tuesday, 19 February 2019, 16:00 – 19:00

Registration: www.empa-akademie.ch/3D-Druck.

The event is free of charge.

| Audio |

Radio programme on SRF1 of 28 June 2019 in German.

-

Share