| |

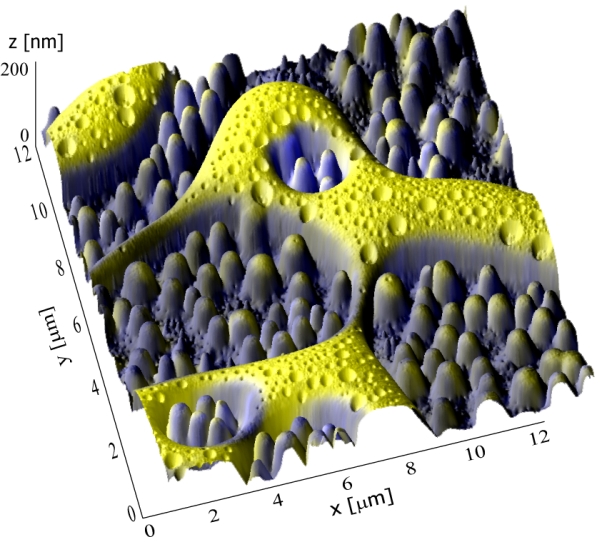

| Das

Resultat einer kombinierten, dreidimensionalen

ToF-SIMS-/SFM-Oberflächenanalyse einer

PCBM/CyI-Polymermischung, die in der Empa-Abteilung

«Funktionspolymere» zur Herstellung organischer

Solarzellen verwendet wird. |

| |

| Was

haben ein Pinguin und die Oberfläche einer Solarzelle

miteinander zu tun? Nicht viel, gibt Empa-Physikerin Laetitia

Bernard zu. Doch hätte sie schmunzeln müssen, als sich

bei der Bearbeitung des Abbilds einer Polymermischung, die für

die Herstellung von neuartigen organischen Solarzellen

benötigt wird, an einer bestimmten Stelle immer deutlicher die

Umrisse eines Pinguins herausschälten. Ein kleines Detail in

der komplexen Welt der Hochleistungsmikroskopie. Das an der Empa

entwickelte 3D-NanoChemiscope bildet Proben nicht nur

nanometergenau ab, sondern kann auch erstmalig präzis

Aufschluss darüber geben, welche chemischen Elemente sich in

einer Probe wo angeordnet haben. Simultan und dreidimensional

lassen sich damit mechanische Eigenschaften wie Härte,

Elastizität oder Reibungskoeffizient, aber auch die chemischen

Eigenschaften von Oberflächenstrukturen bestimmen. Im Falle

des «Pinguin»-Bildes heisst das: das 3D-NanoChemiscope

erfasst nicht nur die Umrisse des «Pinguins», sondern

deckt auch auf, welche Polymere sich auf seinem

«Schnabel», auf seinem «Auge» und «um

ihn herum» angesiedelt haben. Mithilfe dieser Analyse

können die SolarzellenforscherInnen effizient die Mechanismen

ihrer Materialien kontrollieren und entsprechend Zusammensetzung

oder Konzentration ihrer Polymermischung ändern. So lassen

sich neue Strukturen und somit auch andere Eigenschaften für

die Solarzelle herbeiführen. |

| |

|

| |

|

|

|

Einige der

vielen einzelnen Bilder, aus denen das 3D-NanoChemiscope die

3D-Ansicht generierte. Mit dem SFM wird die Oberfläche

topographisch abgebildet (Das Bild links zeigt einen 12µm x

12µm grossen Ausschnitt. Die im Bild sichtbaren

Höhenunterschiede betragen 100-200nm). Mit dem TOF-SIMS kann

gezeigt werden, wo sich die verschiedenen Stoffe, bzw. Polymere der

Polymermischung auf der Oberfläche angesiedelt haben (Bilder

Mitte und rechts zeigen C-+C2- und CN-+I-

Ionen). |

| |

|

| |

Rasterkraftmikroskop und High-End-Massenspektrometer

Möglich macht diese Analyse das 3D-NanoChemiscope,

das zwei bisherig unabhängige Techniken vereint. Das

Rasterkraftmikroskop (SFM, von engl. «scanning force

microscope») rastert mit einer ultrafeinen Nadel die

Oberfläche ab, das High-End-Massenspektrometer (ToF-SIMS, von

engl. «time-of-flight secondary ion mass spectrometry»)

ermittelt, aus welchen Stoffen sich die oberste monomolekulare

Schicht der Festkörperoberfläche zusammensetzt, indem

Ionenstrahlen das Material «beschiessen». |

| |

| Wollte

man bis anhin Oberflächen sowohl auf chemische als auch auf

physikalische Eigenschaften untersuchen, so musste die Probe in

zwei verschiedenen Geräte analysiert werden. Doch durch das

Hin- und Hertragen vom einen zum anderen Gerät lief man immer

Gefahr, die Probe zu verschmutzen oder zu oxidieren. Ausserdem war

es praktisch unmöglich, die im SFM untersuchte Stelle exakt

wiederzufinden. Was lag also näher, als die beiden Geräte

zu «vereinen»? Damit stiessen die Physikerinnen und

Maschinenentwickler bis anhin an ihre Grenzen. In einem

vierjährigen, von der EU geförderten Projekt entwickelte

Projektleiterin Laetitia Bernard mit Empa-ForscherInnen und

Partnern aus Akademie und Industrie in akribischer Arbeit ein neues

Gerät, in dem ein SFM und ein ToF-SIMS in einer

Ultrahochvakuumkammer möglichst nah nebeneinander angeordnet

sind. |

| |

|

| |

|

|

|

Sasa

Vranjkovic, Maschinenbauer, und Laetitia

Bernard, Leiterin des Projekts 3D-NanoChemiscope, diskutieren

den Konstruktionsplan eines Bauteils. |

| |

|

| |

| Die

MikroskopexpertInnen rüsteten das 3D-NanoChemiscope dazu mit

einem neuartigen, eigens entwickelten Transportsystem aus, das die

Probe auf einer Schiene mit einer Beschichtung aus

diamantähnlichem Kohlenstoff (DLC) mittels Piezomotor sanft

hin- und herschiebt. Der Probenhalter kann Bewegungen auf fünf

Achsen ausführen, sodass sich die zu untersuchende Stelle aus

den unterschiedlichsten Positionen analysieren lässt. |

| |

| Nach

seiner Fertigstellung steht der Prototyp – ein Ungetüm

aus glänzendem Aluminium, 1 Meter lang, 70 Zentimeter breit

und an die 1 Meter 70 hoch – nun beim Projektpartner ION-TOF

GmbH im deutschen Münster im Einsatz und wird von

Industriekunden und Forschungspartnern genutzt. Der Bau weiterer

Geräte steht an, Kunden zeigen sich sehr interessiert und sind

bereit, Beträge im siebenstelligen Frankenbereich dafür

zu bezahlen. |

| |

| |