|

Processes which lend materials new characteristics are generally complicated and therefore often rather difficult to reproduce. So surprise turns to astonishment when scientists report on new methods which not only produce outstanding results despite the fact that they use economically priced starting materials but also do not need expensive instrumentation.

Just a simple framework made of polystyrene

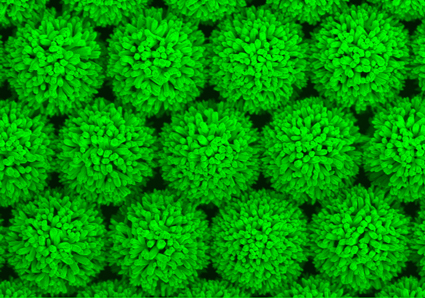

This is exactly what Jamil Elias and Laetitia Philippe of Empa’s Mechanics of Materials and Nanostructures Laboratory in Thun have succeeded in doing. They used polystyrene spheres as a sort of scaffolding to create three-dimensional nanostructures of semiconducting zinc oxide on various substrates. The two scientists are convinced that the (nanostructured) «rough» but regularly-structured surfaces they have produced this way can be exploited in a range of electronic and optoelectronic devices such as solar cells and also short wave lasers, light emitting diodes and field emission displays.

|