Rubber production

Renewable cellulose-based fillers

The substitution of petrochemical materials with those obtained from renewable raw materials is an important step towards increasing sustainability. In just two years of intensive and open collaboration between Empa and the Datwyler Schweiz AG as part of an Innosuisse project, a process was successfully developed that brought together the worlds of cellulose and rubbers.

The substitution of petrochemical materials with those obtained from renewable raw materials is an important step towards increasing sustainability. Materials derived from plant cellulose are promising candidates for this application area. They are renewable, abundant and have a low environmental impact. In the rubber industry, microfibrillated cellulose (MFC) is receiving a lot of attention due to its high stiffness, the morphology of its fibrils, its low density and its mechanical properties. Thus, it has a high potential to improve the properties of rubber compounds.

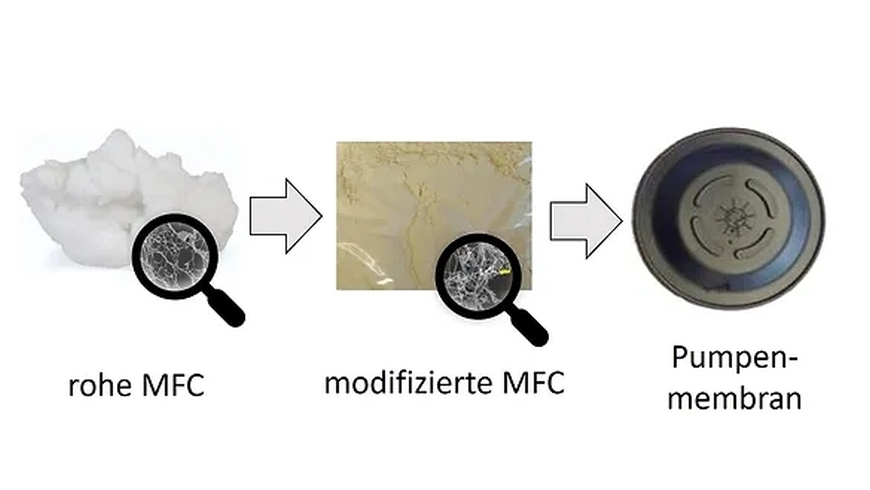

However, it is a challenge to blend MFC with hydrophobic, i.e. water-repellent, rubbers. Together with its development partner Empa, Daetwyler has developed an industrial process for the surface modification of MFC to solve this challenge. Initial trials involved replacing petrochemical aramid fibers with modified MFCs.

The results show good compatibility between the MFC filler and the rubber matrix with strong reinforcing effects, even better than those achieved with conventional petroleum-based aramid fibers. The development of these novel fillers will be an important step towards increasing the sustainability of rubber products such as pump diaphragms.

Two years from research to industy implementation

In just two years of intensive and open collaboration between Empa and the Datwyler Schweiz AG as part of an Innosuisse project, a process was successfully developed that brought together the worlds of cellulose and rubbers. In this short time, it was possible to cover the entire arc from research to industrial implementation.

"This project is a very good example of how valuable Innosuisse's support is for such successful innovation projects, which not only strengthen and economically advance the companies themselves through novel products and processes, but ultimately also the entire location of Switzerland", says Empa researcher Thomas Geiger.

Dr. Thomas Geiger

Empa, Cellulose & Wood Materials

phone: +41 58 765 4723

Dr. Mattia Alberto Lucchini

Datwyler Schweiz AG, Head of Wearable Sensors Development

phone: +41 41 875 13 14

Rainer Klose

Communication

Phone: +41 58 765 4733

redaktion@empa.ch

Liu, M.; Hoffmann, K. G.; Geiger, T.; Nyström, G. Chapter 10 - Production of microfibrillated cellulose fibers and their application in polymeric composites. In: Micro and Nano Technologies, Nanotechnology in Paper and Wood Engineering, Elsevier, 2022; pp 197-229, doi:10.1016/B978-0-323-85835-9.00003-9.

-

Share