|

Load experiments with a nanoindenter

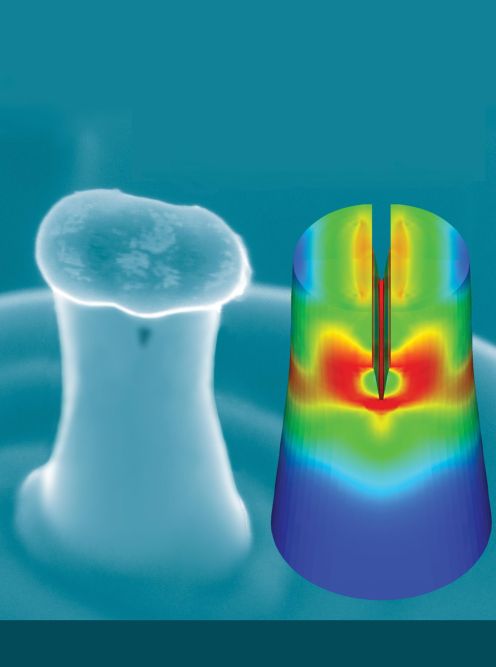

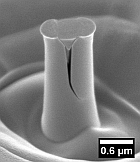

«Our pillar-bending tests are in principle the same as Tetmajer’s experiments, only our pillars are about a hundred thousand times smaller,» says Michler. To apply a force to the columns the scientists used a micro- and nano precision tool called a nanoindenter, where the flattened tip of a pyramid-shaped diamond tool, mounted in a scanning electron microscope, presses down along the longitudinal axis of a silicon column. The force exerted by the tip is continuously measured. «Larger» pillars developed cracks when loaded and broke into small pieces, showing the typically brittle behavior of silicon.

However, when the columns had diameters of less than 400 nanometers, no cracks developed and the structures began to suffer plastic deformation. The reason for this lies in the internal structure of the silicon – its material properties are not determined by the perfect arrangement of the atoms but by the flaws in the arrangement. If the dimensions of the column are smaller than the average distance between defects in the atomic structure of the material then the columns can easily be deformed. Oestlund and Michler, together with their research partners from the Universities of Uppsala and Minnesota, recently published these results in «Advanced Functional Materials», a respected international scientific journal.

|