Monitoring & Diagnostics

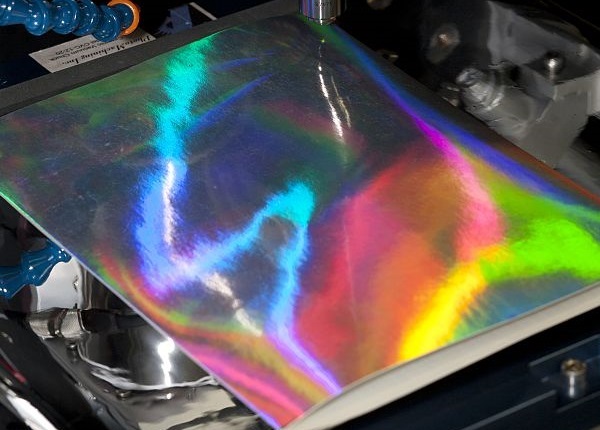

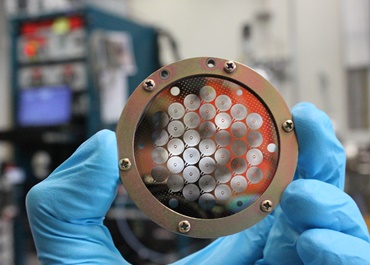

Reliable, economic, and ecological process routes are crucial, with process monitoring emerging as a future technology with significant market potential. Combining material science expertise with advanced sensor technology and data-driven methods enables predictive maintenance, and laser-based manufacturing approaches are being adapted to broader advanced material processing fields.

Process routes do not only need to be economic and ecological, they also need to be reliable. Therefore, we consider process monitoring as a future technology with huge market potential. More and more companies are transitioning from an on-demand service model to predictive maintenance approaches. In order to do so, deep domain knowledge in material and manufacturing science needs to be combined with the right sensor technology, data acquisition and data treatment to combine classical with data-driven approaches. Based on our core competence of laser-based material manufacturing, we will generalize our approaches to other fields of advanced materials processing.

-

Share