Module 2 - Structures & Systems

There is an ever increasing need in our society for building modern structures and for the renovation and conservation of existing infrastructure. The module Structures and Systems is concentrated on the following objectives:

- development of smart structures, digitally fabricated structures and novel systems;

- implementation of novel materials and their integration into compound structures;

- extension of the service life through new repair and strengthening solutions (e.g. with shape memory alloys (SMA) or fiber-reinforced polymer (FRP) patching).

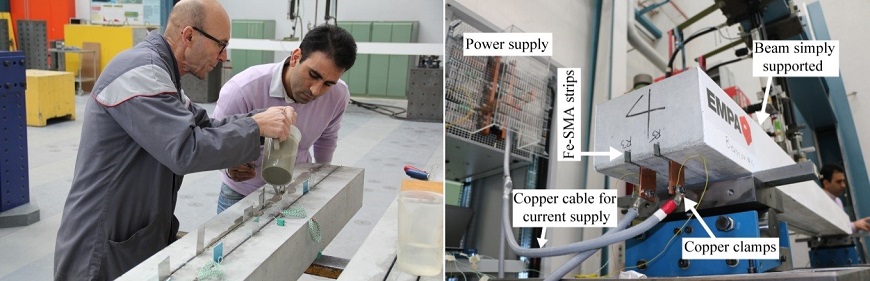

Digital fabrication in construction (e.g. 3D printed concrete) is one of the new topics at Empa and worldwide. In this module, research projects to develop prestress-strategies for 3D printed concrete elements by the use of shape memory alloys and/or carbon fiber reinforced plastics are pursued.

Another topic in this module is the development of materials and systems that reduce the emission and transmission of sound and vibration. One main goal is the reduction of sound transmission in lightweight systems, which are experimentally characterized and analyzed in Empa’s acoustic and noise control lab.

Empa’s extensive experience in the area of safety, reliability assessment and rehabilitation of structures is another key component within this module and complements our building materials research. Structural health monitoring requires systems to continuously assess the structural integrity and hence enable the safe use of the infrastructure in question. The development of robust and affordable sensor networks and related electronics hardware and software for signal processing and transmission as well as of efficient algorithms for data evaluation is of paramount importance to achieve this goal.

There is a huge economic and ecological potential in the renewal, strengthening and upgrading of existing structures, e.g. tunnels, bridges and buildings. A prime example are the various methods for the reinforcement of concrete, steel and aluminum members through external adhesive bonding of unstressed and prestressed carbon FRP laminates, developed by Urs Meier and co-workers. These technologies are used worldwide today and explain Empa’s pioneering reputation in this field.

We continue to be at the forefront of developing new strengthening techniques. Over the last two decades, Empa’s SMA team has been involved in the development and structural application of a cost-effective iron-based SMA, so-called memory steel. Empa memory steel is being produced at industrial scale and has already been used on site in more than 50 real-world applications.

-

Share